I-Welding indlela yokuxhuma ethembekile kakhulu, esetshenziswa kabanzi ekukhiqizeni kwezimboni emhlabeni. Inqubo efanelekile ye-welding ingaqinisekisa ukuthi ukuhlangana kwe-welding kuqinile futhi kuvuza mahhala, ngakho-ke kungadlala indima ebaluleke kakhulu yokuxhumana.

Kunezinhlobo ezimbili ezivamile ze-welding: i-socket welding kanye ne-butt welding

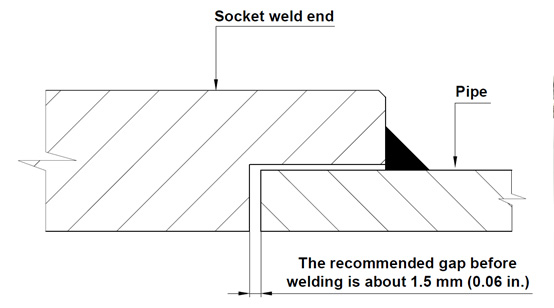

Socket welding: Faka ipayipi emgodini wesinyathelo endaweni yokugcina ye-socket welding bese wephuza umbuthano ongaphandle ukuze uqede ukuxhumana kwe-welding yesokhethi. Ngesikhathi sokushiswa kweSocket, faka ipayipi emgodini we-welding we-socker kuze kube yilapho ifinyelela phansi, bese ikhipha ipayipi cishe nge-1.5mm (0.06in.

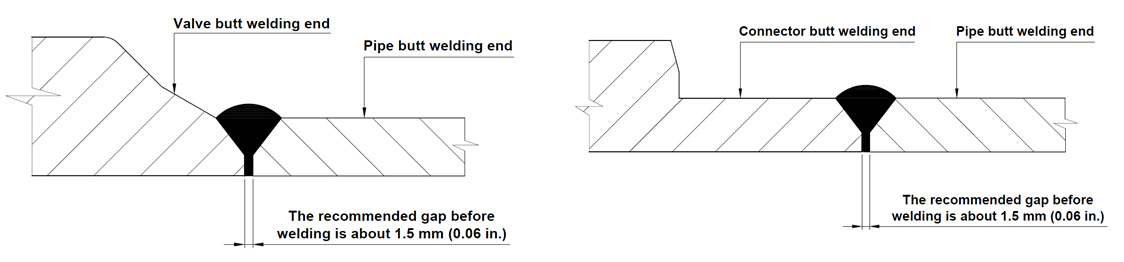

Butt welding: Amalunga we-welding ama-weldentiment emaphethelweni womabili azophaphama, kanye ne-1.5mm (0.06in.) Kuzogcinwa. Ngemuva kwalokho wembula umbuthano eceleni kokuhlanganiswa ukuze uqinisekise ukuthi udonga lwamapayipi lufakwe ngokuphelele ukuthola amandla athembekile. Njengoba kukhonjisiwe kwisibalo, i-valve ene-butt welding uxhumano ingafakwa i-butt ngepayipi, futhi ukufakwa kwezilwandle kungahle kube yi-butt ngepayipi.

Umsebenzi wokucaciswa kwe-Welding

Izisebenzi ze-welding ze-hikelok zidlulise ukuqeqeshwa kanye nokuhlola okungochwepheshe, futhi zisebenzisa ngokuqinile inqubo ye-welding ngesikhathi se-welding ukuqinisekisa ukuthi ukubukeka, ukusebenza kanye nokusebenza kwemikhiqizo kufinyelela isimo esifanelekile ngemuva kokushiswa.

Imikhiqizo ye-Hikelok Welding ifakai-valve yenaliti, I-Ball valve, ukufakwa okufuyiwe, njll., Okungahle kwenziwe ngokwezifiso ngokuya ngezimo zokusebenza zamakhasimende.

Ngemininingwane eminingi yoku-oda, sicela ubheke ekukhetheniamakhathalogiphezu kwa-Iwebhusayithi esemthethweni yeHikelok. Uma unemibuzo yokukhetha, sicela uthinte abasebenzi abasebenza ngokuthengisa abasebenza ngehora lama-24.

Isikhathi sePosi: APR-27-2022