Lapho uklama uhlelo lwensimbi evaliwe, isinyathelo sokuqala sokuqinisekisa ukuphepha nokwethenjwa kohlelo ukukhetha insimbi efaneleithumbuukufeza inhloso elindelekile. Ipayipi elifanele lezinsimbi lidlala indima ebalulekile maqondana futhi liyahambisana nezinye izakhi. Ngaphandle kwepayipi elifanele lezinsimbi, ubuqotho bohlelo aluphelele. I-Hikelok izinsimbi zepayipi zisetshenziswa kabanzi ngezikhathi ezahlukahlukene ezidinga ukusebenza okuhle kakhulu kwemikhiqizo. Ukuhambisana kweHikelok izithuthi zezinsimbiFuthi amashubhu ethuluzi akhethiwe kubalulekile ukuhlinzeka ngokwethembeka okuphezulu okungaguquki.

1. Ukuvumelana okubonakalayo

Into ebaluleke kakhulu okufanele uyicabangele lapho ukhetha amapayipi ensimbi afanele ezicelo ezahlukahlukene ukuhambisana phakathi kwepayipi kanye ne-medium equkethwe.

2. Ubulukhuni be-tube yensimbi

Ukhiye ukukhetha impahla yamapayipi ngobulukhuni obuncane kunempahla yamapayipi. Isibonelo, ubulukhuni bensimbi obungenasici kufanele bube yi-RB 80 noma ngaphansi. I-Hikelok tubing ihlolwe ku-RB 90 Hardness Grade Pear, futhi ukusebenza kokuhlola kuhle kakhulu.

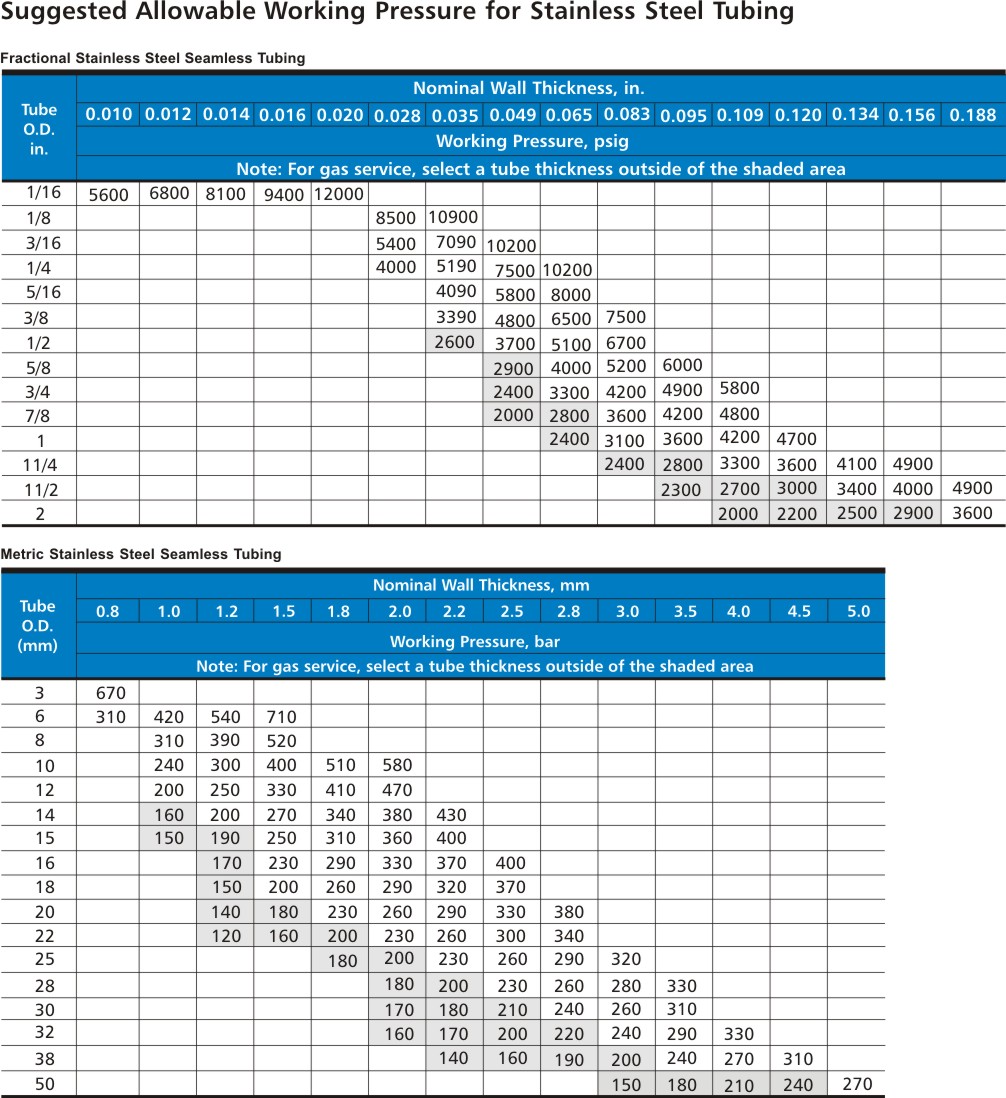

3. Ubukhulu bodonga

Ubukhulu bodonga olufanele kuyadingeka ukuze uhlangabezane nento eyaziwayo yokuphepha ehambisana nengcindezi yokusebenza. Umdwebo we-rube wensimbi olwazini lomphakathi we-hikelok uhlu lwenhlanganisela yesayizi ye-OD kanye nodonga oluncane lwe-tubing. Kwenqatshelwe ukusebenzisa ishubhu lensimbi elidonsayo odonga oludlula inani elishiwo eshadini.

Zonke izingcindezi zokusebenza zibalwa ngokuhambisana ne-ASME B31.3 Ukucaciswa kwesitshalo samakhemikhali kanye nokuhlanza umzimba kanye ne-ASME B31.1 ithuluzi lamandla. Zonke izibalo ziqinisekiswe yizinqubo zokuhlola ezinzima nezibanzi atHikelok r & d laworatories. Ukubalwa ngakunye kusebenzisa inani lokucindezela elivumelekile, okubandakanya isici sokuphepha esingu-4: 1.

Zonke izivivinyo zenzelwe ukulingisa imvelo yangempela yokusebenza ngangokunokwenzeka. I-Hikelok ayisekeli ukwehluleka kwe-tube yensimbi ethile endaweni ethile, ngoba ayimeleli ngempela iqhaza lemikhiqizo ye-hikelok ku- "real-time" application.

4. Ukushisa okuphezulu

Ingcindezi yomhlangano weTubing akufanele idlule ingcindezi yokusebenza enconyiwe. Amamaki okuqinisekisa okumbili, njenge-316 / 316l, ahlangane nezidingo ezisezingeni eliphansi zamakhemikhali nezemishini zamabanga amabili alloy.

Isikhathi sePosi: Feb-22-2022