Ukusebenza kohlelo lwamanzi olumbonini kuncike ekubambisaneni kwengxenye ngayinye enikezela ngoketshezi lwenqubo yakho lapho iya khona. Ukuphepha nokukhiqiza kwesitshalo sakho kuxhomeke ekuxhumekeni kwamahhala okuhambisanayo phakathi kwezakhi. Ukuhlonza okufanelekile ngohlelo lwakho lwe-fluid, qala ngokuqonda futhi ukhombe usayizi wentambo kanye ne-pitch.

Intambo nokupheliswa kwesisekelo

Ngisho noma ochwepheshe abanolwazi kwesinye isikhathi bakuthola kunzima ukukhomba imicu. Kubalulekile ukuqonda ukuqonda okujwayelekile kanye nemigomo yokuqedelwa kwamazinga okusiza ukuhlukanisa imicu ethile.

Uhlobo lwentambo: intambo yangaphandle kanye nentambo yangaphakathi kubhekisele isikhundla sentambo kokuhlanganiswa. Intambo yangaphandle iphuma ngaphandle kokuhlanganiswa, ngenkathi intambo yangaphakathi ingaphakathi kokuhlanganiswa. Intambo yangaphandle ifakwe emgqeni wangaphakathi.

Iphimbo: I-pitch ibanga phakathi kwentambo. Ukukhonjwa kwe-Pitch kuncike emazingeni athile wentambo, njenge-NPT, i-ISO, i-BSPT, njll. I-pitch ingavezwa ngemicu nge-intshi ngayinye ne-MM.

I-AngerNendum and Dedendum: Kukhona iziqongo nezigodi ku ntambo, ezibizwa ngokuthi i-addendum ne-desendum ngokulandelana. Indawo ephansi phakathi kwethiphu nempande ibizwa ngokuthi i-flank.

Khomba uhlobo lwentambo

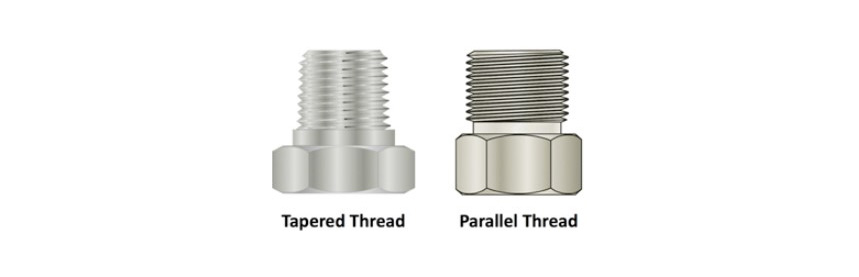

Isinyathelo sokuqala ukukhomba usayizi wentambo futhi iphimbo ukuba namathuluzi afanele, kufaka phakathi i-vernier caliper, i-pitch gauge kanye nomhlahlandlela wokuhlonza we-pitch. Basebenzise ukuthola ukuthi intambo igcwele noma iqonde. I-Tapered-Thread-vs-Straight-Thread-Umdwebo

Intambo eqondile (ebizwa nangokuthi intambo efanayo noma intambo yemishini) ayisetshenziselwa ukubopha uphawu, kepha isetshenziselwa ukulungisa i-nati emzimbeni wesixhumi se-Consing. Kumele bathembele kwezinye izinto ukuthi bazokwakha izimpawu zokuvuza ubufakazi, njengeama-gaskets, o-izindandatho, noma insimbi ekutholeni insimbi.

Imicu ye-tapered (eyaziwa nangokuthi imicu enamandla) ingavalwa lapho izinyo lezinyo lemicu yangaphandle neyangaphakathi lidonswa ndawonye. Kuyadingeka ukusebenzisa i-hind sealant noma umucu wentambo ukugcwalisa igebe phakathi kwethiphu yezinyo nezamazinyo izinyo ukuvimbela ukuvuza kokulufu kohlelo ekuhlanganiseni.

Intambo ye-taper ise-angle kulayini wesikhungo, ngenkathi intambo efanayo ifana nomugqa wesikhungo. Sebenzisa i-vernier caliper ukukala ithiphu kububanzi be-tip yentambo yangaphandle noma intambo yangaphakathi kwintambo yokuqala, yesine neyedlule. Uma ububanzi bukhuphuka emaphethelweni owesilisa noma wehlise ekugcineni kwabesifazane, intambo igcwele. Uma wonke amadayimitha efana, intambo iqondile.

Ukulinganisa ububanzi bentambo

Ngemuva kokuthi ukhombe ukuthi ngabe usebenzisa imicu eqondile noma eqondile, isinyathelo esilandelayo ukuthola ububanzi bentambo. Futhi, sebenzisa i-vernier caliper ukukala intambo yangaphandle yokuqamba noma ububanzi bentambo yangaphakathi kusuka phezulu kwezinyo kuya phezulu kwezinyo. Ngemicu eqondile, ukukala noma iyiphi intambo ephelele. Ngemicu ye-tapered, ukukala intambo yesine noma yesihlanu egcwele.

Izilinganiso zobubanzi ezitholakele zingahluka ngosayizi bezintambo ezinikezwe zohlu. Lolu shintsho ngenxa yokubekezelelana okuhlukile kwezimboni noma zokukhiqiza. Sebenzisa umhlahlandlela wokuhlonza umucu womakhi we-Connect. intambo-pitch-gauge-isilinganiso-isilinganiso

Thola iphimbo

Isinyathelo esilandelayo ukunquma iphimbo. Bheka intambo ngokumelene nesimo ngasinye nge-pitch gauge (eyaziwa nangokuthi ikamu) kuze kutholakale umdlalo ophelele. Amanye ama-Shapes athile wentambo yesiNgisi neye-metric afana kakhulu, ngakho-ke kungathatha isikhathi.

Sungula I-Pitch Standard

Isinyathelo sokugcina ukusungula i-Pitch Standard. Ngemuva kocansi, thayipha, ububanzi bemizi kanye ne-pitch yentambo kunqunywa, i-Thrent portal Standard ingakhonjwa umhlahlandlela wokuhlonza umucu.

Isikhathi sePosi: Feb-23-2022