Ukuze uqinisekise ukusebenza kweTwin Ferrule Tube FittingsNgokuya ngokumelana nokugqwayiza, ukubekwa uphawu, ukumelana nokucindezela kanye nokuvinjwa kokudlidliza, sasampula imikhiqizo evela kumabhendi ahlukene ngokuhambisana nalokhoI-ASTM F1387, ABSkanye nokucaciswa okuhlangene kwenuzi zenuzi, futhi kwenziwa izivivinyo ezilandelayo zokuhlola. Imiphumela ikhombisa ukuthi bonke badlula.

Isivivinyo Sokuhlola

| Umphumela | Uhlobo lokuhlola | Inqubo yokuhlola | Umphumela wokuhlola |

| Ukufakwa kabili kwe-Ferrule Tube | Ukuhlolwa kwe-Vibration | Ukuhlolwa kwe-vibration kwenziwa kwizikhombisi-ndlela ze-X, y kanye no-Z Imvamisa yokuhlola iphakathi kuka-4 ~ 33hz, futhi akukho ukuvuza ngesikhathi senqubo yokuhlola. | Dlula |

| Ukuhlolwa kwengcindezi ye-Hydraulic Profact | I-Test Medium amanzi ahlanzekile, ingcindezi yokuhlola yisikhathi esingu-1.5 ukucindezela okusebenzayo, isikhathi sokubamba ingcindezi siyi-5min, futhi kufanelekile. | Dlula | |

| Ukuhlolwa kokumelana nokugqwala | Isivivinyo sokufafaza usawoti sokufaneleka kwensimbi engenasici kwenziwa amahora angama-168, futhi kwakungekho ndawo yokugqwala. | Dlula | |

| Ukuhlolwa kobufakazi be-pneumatic | I-Test Medium yi-nitrogen, ingcindezi yokuhlola izikhathi eziyi-1,25 umfutho osebenzayo, futhi ingcindezi igcinwa nge-5min ngaphandle kokuvuza. | Dlula | |

| Ukuhlolwa kwe-Impulse | Ingcindezi yokuphamba ikhuphuka isuka ku-0 ibe ngu-133% yengcindezi yokusebenza, bese inciphisa ingcindezi yokungabi ngaphezu kwama-20 ± 5% wengcindezi ekalwe. Isamba sesikhathi sokucindezela kanye nesikhathi sokuqothula kungumjikelezo. Ngemuva kokuthi umjikelezo ungaphansi kwezikhathi eziyi-1000000, akukho ukuvuza. | Dlula | |

| Ukuvikelwa kokukhishwa kanye nokuhlola kabusha | Azikho ngaphansi kwezikhathi eziyi-10 ze-Interpenetation kanye nokuqinisekiswa kokuhlolwa ngakunye ngaphandle kokuvuza. | Dlula | |

| Ukuhlolwa kwe-Thermal Cycle | Ngaphansi kwengcindezi yokusebenza, ucezu lokuhlola luzogcinwa emazingeni okushisa aphansi - 25 ℃ kumahora ama-2, bese ucezu lokuhlola luzogcinwa ekushiseni okuphezulu kwama-80 ℃ kumahora ama-2. Ukusuka emazingeni okushisa aphansi kuya ekushiseni okuphezulu kungumjikelezo, ohlala imijikelezo emi-3. Ngemuva kokuhlolwa kwe-hydraulic, akukho ukuvuvukala. | Dlula | |

| Donsela isivivinyo | Faka umthwalo ongapheli wethanga ngejubane elingama-1.3mm / min (0.05in / min). Ngalesi sivinini, finyelela inani elibaliwe elivumelekile le-tensile umthwalo wenani, i-ferrule ayihlukaniswa nokufanele, futhi akukho ukuvuvukala nomonakalo ovivinyweni lwe-hydrostatic. | Dlula | |

| Ukulinda ukukhathala | 1. I-specimen ifinyelela inani lokugoba elidilikayo elidingwa yi-F1387 ngaphansi kwengcindezi yokusebenza ekalwe, 2 3. Yenza imijikelezo engu-30000 ephelele esiqeshini sokuhlola, futhi akukho ukuvuvukala ngesikhathi sokuhlolwa. | Dlula | |

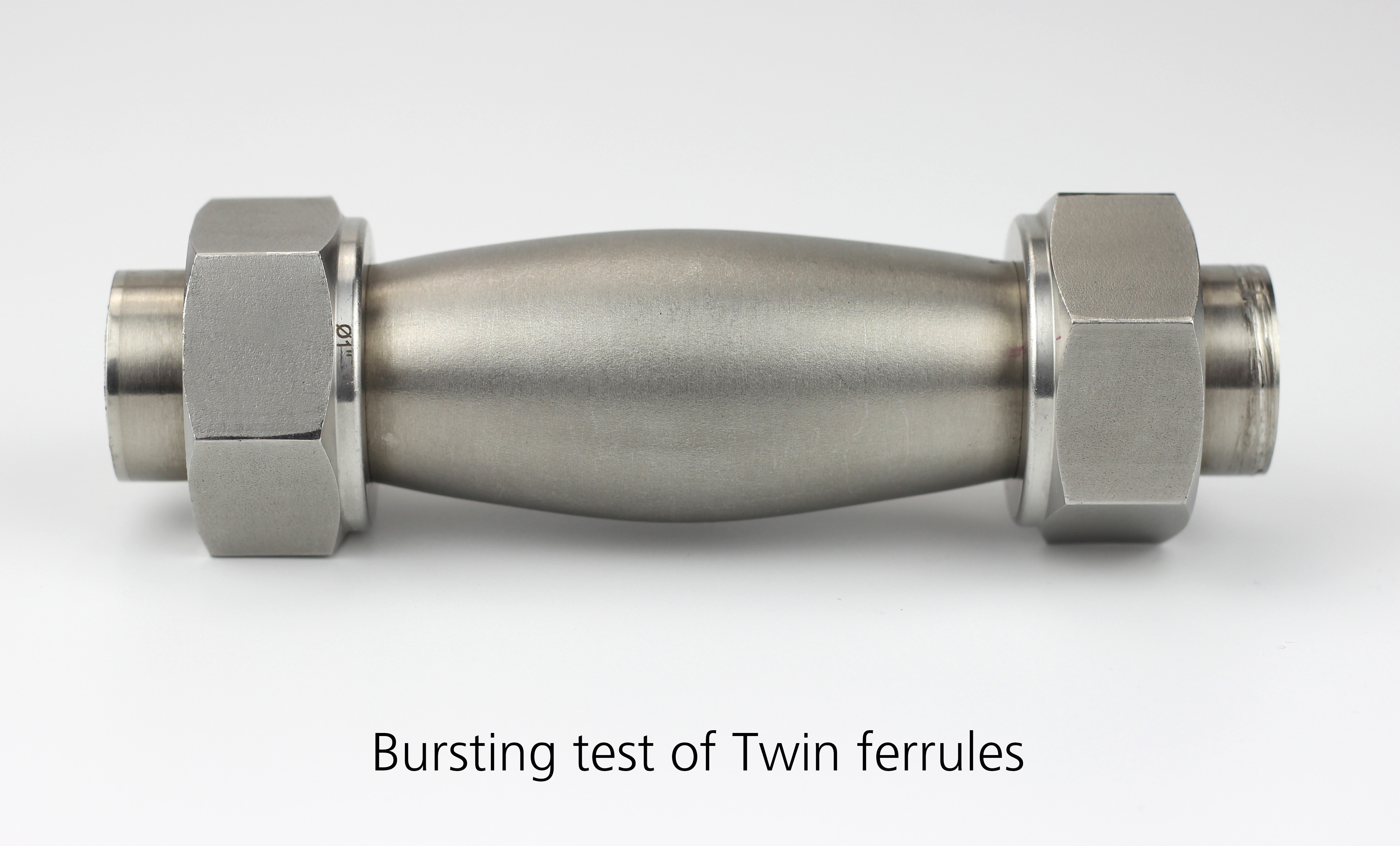

| Ukuhlolwa kwengcindezi | Cindezela ucezu lokuhlola izikhathi ezi-4 zokucindezela okusebenzayo kuze kube yilapho kuqhuma ishubhu, futhi ama-fertures akhululekile ekuweni nokuvuza. | Dlula | |

| Ukuhlolwa kwe-Rotational Deflection Test | 1. Yethula umzuzu wokugoba ngokusho kwe-F1387 bese uyikhiya endaweni. 2 3 | Dlula | |

| Ukuhlolwa kwe-torque ngaphezulu | Bopha ucezu lokuhlola ngethuluzi elifanelekile futhi ujikeleze enye ukuphela kuze kube yilapho ishubhu ichithwa unomphela noma ichithwe isihlobo esifanele futhi akukho ukuvuvukala esivivinyweni se-hydrostatic. | Dlula

|

Ngemininingwane eminingi yoku-oda, sicela ubhekeI-Hikelok esemthethweni esemthethweni. Uma unemibuzo yokukhetha, sicela uthintane nabasebenzi abasebenza ngehora lama-24.

Isikhathi sePosi: Feb-24-2022