I-welding yindlela ethembekileyo yoqhagamshelo, esetyenziswa ngokubanzi kwimveliso yemizi-mveliso ehlabathini. Inkqubo echanekileyo ye-welding inokuqinisekisa ukuba i-Welding Graint iqinile kwaye ivuza yasimahla, ukuze idlale indima yonxibelelwano ebaluleke kakhulu.

Zimbini iindlela eziqhelekileyo ze-wels: isokisi ye-welding kunye ne-bludy welding

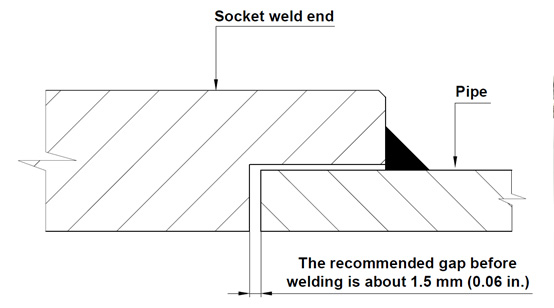

Isokisi ye-welting: Faka umbhobho kwinyathelo lenyathelo kwisiphelo se-Welke yeSokethi kwaye uluphele isangqa ngaphandle ukuze ugcwalise unxibelelwano lwe-Welding ye-Welding. Ngexesha lezithole, faka umbhobho kwisokisi yesokisi kwaye ufike ezantsi, emva koko ukhuphele umbhobho malunga ne-1.5mm (0.), emva koko iphephe i-welding ngexesha le-welding.

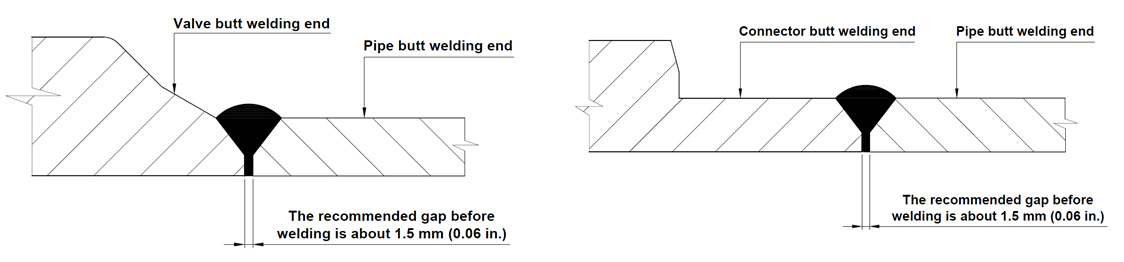

I-bluld welding: Amalungu angama-welding yeZiphelo ezibini aya kuhlukumeza, kwaye i-1.5mm (i-0.0min.) iya kugcinwa. Emva koko salld isangqa ecaleni kweNtlalothi yokuqinisekisa ukuba udonga lombhobho lwenziwe ngokupheleleyo ukufumana amandla athembekileyo. Njengoko kubonisiwe kumzobo, ivalve enoxuko lwe-Woot Welling linokuba yi-Welded ngombhobho, kwaye i-filtings ye-welding inokuba ne-buted ngemibhobho.

Ukusebenza kwe-welding

Abasebenzi be-hikhilok baphumelele uqeqesho lobuchule novavanyo, kwaye besebenzisa ngokungqongqo inkqubo ye-welding ngexesha lokuqinisekisa ukuba inkangeleko, ukusebenza kunye nokusebenza kweemveliso kufikelela kwimeko efanelekileyo emva kwe-welding.

I-Hikelok Welding Iimveliso zibandakanyaivalve yenaliti, ivalve yebhola, Izixhobo ze-weldings, njl njl, enokwenziwa ngokwezifiso ngokweemeko zomsebenzi zabathengi.

Iinkcukacha ezi-odolo zoku-odola, nceda ujonge ukhethoiikhathalogukwiIwebhusayithi yaseHikelok. Ukuba unayo nayiphi na imibuzo yokukhetha, nceda uqhagamshelane ne-hipti's iiyure ezingama-24 kwi-Intanethi.

Iposi: Apri-27 ukuya kwi-2022