Ukusebenza kwenkqubo ye-fluid kuxhomekeke kwintsebenzo yecandelo ngalinye elihambisa inkqubo yakho ye-fluid kwindawo yayo. Ukhuseleko kunye nemveliso yesityalo sakho kuxhomekeke kunxibelelwano lwasimahla phakathi kwamacandelo. Ukuchonga ukufaneleka kwenkqubo yakho ye-fluid, qala uqonde kwaye uchonge ubungakanani be-thread kunye nesandi.

Intambo kunye nokupheliswa kwesiseko

Nokuba iingcali ezinamava ngamanye amaxesha zikufumanisa kunzima ukuchonga imisonto. Kubalulekile ukuqonda intambo ngokubanzi kunye nemigangatho yokupheliswa kunye nemigangatho ukunceda ukwahlulahlula imisonto ekhethekileyo.

Uhlobo lwentambo: Intambo yangaphandle kunye nentambo yangaphakathi ibhekisa kwisikhundla sentambo kwiNtlawulo. Intambo yangaphandle ikhusela ngaphandle kweNtlawulo, ngelixa intambo yangaphakathi iphakathi kweNtlanganiso. Intambo yangaphandle ifakwe kwintambo yangaphakathi.

I-pitch: I-pitch ngumgama phakathi kwemisonto. Isichazi-magama se-pitch sixhomekeke kwimigangatho ethile yemitya, enje nge-NPT, i-ISO, i-ISSPP, njl. I-pitch inokubonakaliswa kwimigca kwi-intshi nganye kunye ne-mm.

IsiHlomelo kunye neDedendum: Kukho iincopho kunye neentlambo kwintambo, ezibizwa ngokuba yiHesdendUm kunye ne-Dedendam ngokulandelelana. Umphezulu othe tyaba phakathi kwentloko kwaye ingcambu ibizwa ngokuba yiFlenk.

Chonga uhlobo lwentambo

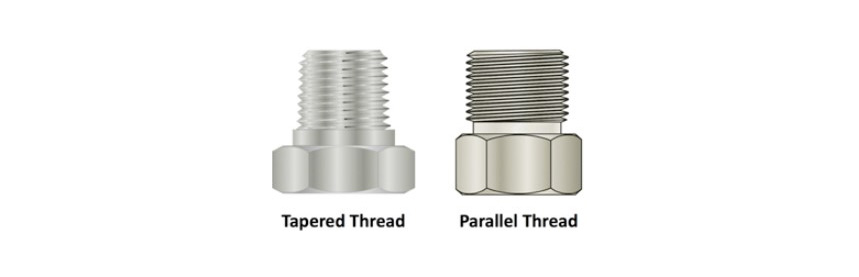

Inyathelo lokuqala lokuchonga ubungakanani be-terican kunye ne-pitch kukufumana izixhobo ezifanelekileyo, kubandakanya ne-vernier caliper, i-vernier gauge kunye nesikhokelo sokuchonga isikhokelo. Zisebenzise ukufumanisa ukuba intambo ithe tye okanye ithe tye. I-Tapered-Tom-vs-vs-thearam

Intambo ethe nkqo (ikwabizwa ngokuba yintambo ye-faralel okanye intambo yoomatshini) ayisetyenziselwa ukutywina, kodwa isetyenziselwa ukulungisa i-nati kwi-National Chenting. Kuya kufuneka baxhomekeke kwezinye izinto zokwenza amatywina ashushu, njengeIirhasi, i-o-rings, okanye isinyithi ukunxibelelana ngokwesinyithi.

Imisonto edityanisiweyo (ekwabizwa ngokuba yimisonto eguqukayo) inokutywina xa amacala amazinyo anemitha yangaphandle neyangaphakathi edityaniswe kunye. Kuyimfuneko ukusebenzisa i-sthy ye-telant ye-telant okanye i-tepe ukugcwalisa i-GAP phakathi kwezibamba zezinyo kunye neengcambu zamazinyo ukukhusela ukuvuza kwenkqubo yenkqubo.

Umsonto we-Taper ikwi-engile ukuya kumgca weziko, ngelixa intambo efanayo ihambelana kumgca weziko. Sebenzisa i-vernier caliper ukulinganisa i-TIT ukuya kububanzi be-Tit yentambo yangaphandle okanye intambo yangaphakathi kwintambo yokuqala, yesine neyokugqibela. Ukuba idayamere inyukele kwisiphelo sendoda okanye incipha ekuphela komfazi, intambo iyanyibilikiswa. Ukuba bonke ububanzi bayalingana, intambo ithe tye.

Ukulinganisa ububanzi

Emva kokuba uchonge ukuba usebenzisa intambo ngqo okanye edityanisiweyo, inyathelo elilandelayo kukufumanisa ububanzi bomsonto. Kwakhona, sebenzisa i-vernier caliper ukulinganisa intambo yangaphandle okanye ububanzi bayo obuvela phezulu kwizinyo ukuya phezulu kwizinyo. Imisonto ethe tye, linganisa nayiphi na intambo epheleleyo. Imisonto edityanisiweyo, linganisa intambo yesine okanye yesihlanu.

Imilinganiselo yedayiti efunyenweyo ingahluka kubukhulu obekiweyo weentambo ezinikiweyo ezidwelisiweyo. Olu tshintsho lubangelwa kukuqina okukhethekileyo kwezorhwebo okanye ubume. Sebenzisa isikhokelo soMvelisi woMvelisi woMvelisi wokuchonga ukufumanisa ukuba ububanzi busondele kubukhulu obuchanekileyo kangangoko kunokwenzeka. I-Thread-Gauge-Gauge-Gauming-Umzobo

Chonga i-pitch

Inqanaba elilandelayo kukuchonga i-pitch. Jonga intambo nxamnye nobume ngasinye nge-pitch gage (ikwabizwa ngokuba ngumgaqo) kude kufunyanwe umdlalo ogqibeleleyo. Ezinye izilonda zesiNgesi kunye ne-metric stores zifana kakhulu, ke zinokuthatha ixesha.

Seka umgangatho we-pitch

Inyathelo lokugqibela kukuseka umgangatho we-putt. Emva kwesondo, uhlobo, ububanzi bendawo kunye nentambo yentambo zimiselweyo, umgangatho wokuchonga intambo unokuchongwa ngesikhokelo sokuchonga intambo.

Ixesha lasemva: Feb-23 ukuya kwi-2322