Welding ke mokhoa o tšepahalang haholo oa khokahano, e sebelisoang haholo tlhahiso ea indasteri lefatšeng. Ts'ebetso e nepahetseng ea ho bopa e ka tiisa hore manyalo a manyane a tiile 'me a tsoa mahala, kahoo e ka bapala karolo ea bohlokoa ka ho fetisisa.

Ho na le mefuta e 'meli e tloaelehileng ea welding: socket welding le stting welding

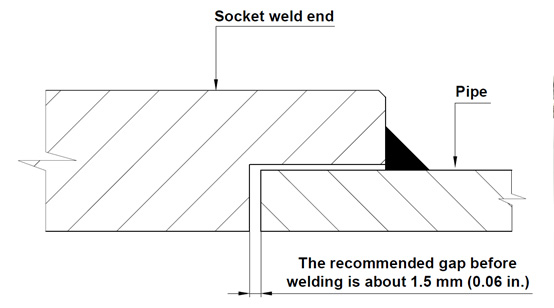

Sokke Soldding: Kenya phala ka sekoting sa bohato ka letshala la bosetlelete e qetellong le selikalikoe se ka ntle ho phethela khokahano ea Soft e lefelloang ka tlase. Nakong ea socket Wipe, kenya phaene ka sekoting sa Socket ho fihlela e fihla tlase, ebe e ntša phala ka 1.5mm (0.06in.), E ka qoba ho soma, e ka qoba ho sokala ka ho phomola.

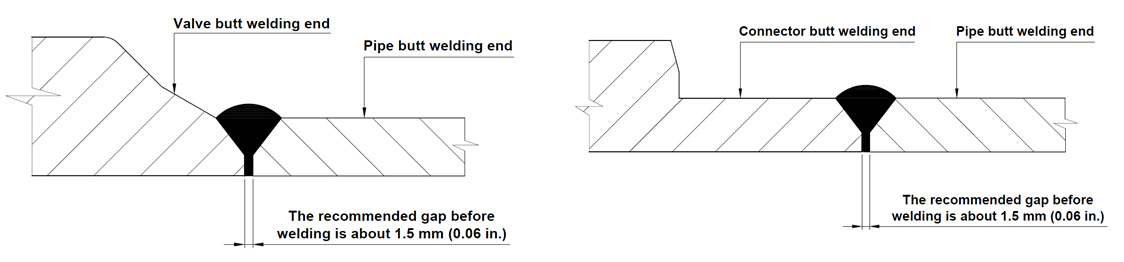

Butt welding: manonyeletso a litefo tsa welterment ka bobeli a tla ba kotsing, 'me 1.5mm (0,06in.) E tla bolokoa. Ebe u tšela selikalikoe ho kopanya hammoho le lenyenyetsi ho netefatsa hore lebota le pobelitsoeng ka botlalo le na le matla a tšepahalang. Joalokaha ho bontšitsoe setšoantšong, valve e nang le khokahano ea Wet West e ka ba e ferekane ka phala, le litebele tsa WAP le tsona li ka tšeptjoa ka phala.

Ts'ebetso ea Bobeli ea Wedding

Basebetsi ba likamore tsa Hikek ba fetile thupelo ea litsebi le tlhahlobo, ba sebelisa mokhoa oa ho etsa o sebelisane le ho tšoarella.

Lihlahisoa tsa Warlok Tseleng li kenyelletsaValve ea Nale, Belve ea Ball, Li-Fittive tse teddileng, joalo-joalo, e ka hlophisoang le eona ho latela maemo a ho sebetsa a bareki.

Bakeng sa lintlha tse ling tse hlophisehileng, ka kopo sheba khethoLibuka tsa libukaHoSebaka sa semmuso sa Hikek. Haeba u na le lipotso tsa khetho, ka kopo ikopanya le basebetsi ba lihora tse 24 tsa Hikelok.

Nako ea poso: Apr-27-1022