Lipuisano tsa indasteri, khetho ea lisebelisoa tsa thuto ea thuto ea thuto ea thuto ea Valgh e bohlokoa ho netefatsa bophelo bo phethahetseng le ba ts'ebeletso. Har'a likhetho tse fapaneng tse fumanehang, lifilimi tsa graphie li totomelletse thepa ea tsona e ikhethang le melemo e mengata. Sengoliloeng sena se hlahloba melemo ea Graphite ho pakela Valvera ea lisebelisoa ka ho khetheha, e totobatsa hore na ke hobaneng ke khetho ea pele indasteri e mengata ea indasteri e mengata.

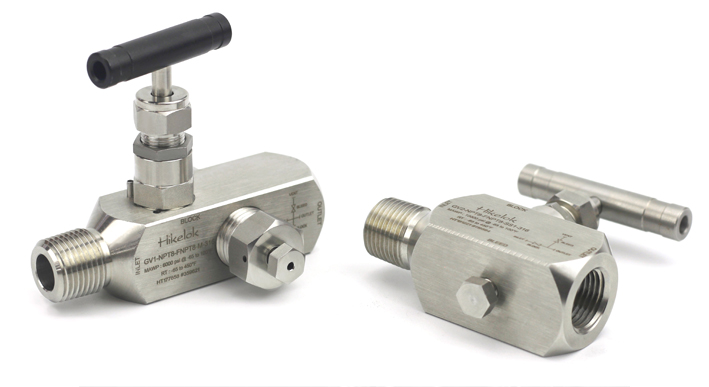

Hikelok e ka fana ka tse fapaneng tsalisebelisoa tsa lisebelisoae nang le paroite e pakiloeng joalo kaLi-valves tsa bolo,Manows,Li-valves tsa nale,Valve ea gauge, Thipa le valve e tsoang hantlejj.

Khanyetso e Ntle ea mocheso ea mocheso

E 'ngoe ea tsebiso ea bohlokoahali ea filler e tloaelehileng ke ho hanana le mocheso haholo. Graphite e ka khona ho mamella lithemparetjha tse feteletseng, maemong a mang, ho tsoa ho lithemparetjha tsa lla ho feta 500 ° F (932 ° F (932 ° F). Sena se etsa hore e be loketseng valves ea lisebelisoa e sebetsang tikolohong e phahameng e kang oli le khase, moloko oa tlhaho. Bokhoni ba ho boloka ba tšepahala maemong a joalo ka netefatse hore val ona bo qala hantle ntle le kotsi ea ho lutla kapa ho se atlehe.

Khokahano e ntle ea lik'hemik'hale ea lik'hemik'hale

Lisebelisoa tsa seletsa hangata li sebetsana le metsi a fapaneng, ho kenyelletsa lik'hemik'hale tse matla le mecha ea litaba. Litšoantšo tsa Graphie li fane ka tšebeliso ea bohlokoa ea lik'hemik'hale, e etsa hore li lokele ho sebelisoa libakeng tseo ho tsona lifoto tse tloaelehileng ho senya kapa ho hloleha. Mefuta ea eona e lumella ho mamella ho supeha ho acid, metheo le likanoteng, ho netefatsa sephutheloana ha nako e ntse e tsamaea le ho sebetsa ka nako. Kamoreng ena ea lik'hemik'hale ha e felise bophelo ba ho paka, empa ho boetse ho boetse ho fokotsa litšenyehelo tsa ho hlokomela chelete e amanang le phetohelo ea khafetsa.

Likhohlano tse tlase le li apare

Monyetla o mong oa li-fileer tsa graphite ke thepa ea bona e tlase ea litonello. Ha e sebelisoa ka har'a li-valves tsa sesebelisoa, paraphite e khabisitsoeng e fokotsa ho roala li-stems le likarolo tse ling, tse hlahisang ts'ebetso e matla le ho fokotsa matla. Karolo ena e molemo haholo lits'ebetsong tseo litsamaisong tsa litsi tsohle kapa li ka tlas'a khatello e phahameng. Phokotso ea likhone e boetse e thusa ho fokotsa mocheso oa mocheso, ho ntlafatsa karolo e fetang ka linako tsohle tsamaisong.

Thepa ea boithati

Graphite ke lubricant ea tlhaho, e bolelang hore e fana ka thepa ea boithati ha e sebelisoa e le filimi. Karolo ena e molemo haholo ho li-valves tsa sesebelisoa hobane e thusa ho fokotsa tlhokahalo ea lubricant e eketsehileng, e leng eona e ka kena-kenana le ts'ebetso ea valve kapa e silafatsang mecha ea litaba e ntseng e tsoela pele. Thepa ea boithati ea ho itaola ea paraphite e tiisa ts'ebetso e boreleli ea valve le tlasa maemo a thata.

Ho fapanyetsana le moetlo

Lifilimi tsa graphite li fapanyetsana 'me li ka etsoa ho fihlela litlhoko tse ikhethileng tsa kopo. E ka etsoa ka mefuta e fapaneng, ho kenyeletsoa libopeho tse halikiloeng tse entsoeng ka ho itlopatsa kapa tse hlahisitsoeng ke lilitlo tsa li-valights tsa li-valve tsa seletsa. Ho ikamahanya le maemo ho etsa hore lifilimi tsa graphite li sebelisoe indasteri ea meriana ea meriana ea meriana ho ea peterochemicals, e netefatsa hore ba ka fihlela litlhoko tse ikhethang tsa kopo e 'ngoe le e' ngoe.

Katleho e theko e boima

Le ha litšenyehelo tsa pele tsa graph li ka phahama ho feta li-mopalanta tse ling tsa setso, hangata melemo ea nako e telele e feta ntlheng e holimo ea matsete. Morero oa filler, litlhohonolofatso tse tlase tsa tokiso le bophelo bo bolelele ba litšebeletso bo kenya letsoho ho boloka chelete e ngata ha nako e ntse e tsamaea. Ka ho fokotsa nako ea ho khutlisa le ho fokotsa nako ea nako, lik'hamphani li ka fumana tharollo e sebetsang e le e boima bakeng sa li-valves tsa tsona.

COrkush

Ka kakaretso, ho na le melemo ea ho paka ha kha-taba ea kha-pele bakeng sa li-valves tsa lisebelisoa li ngata ebile li le linyehisang. Lintho tsa mocheso oa eona tse phahameng tse phahameng, kamohelo e ntle ea lik'hemik'hale, likhohlano tse tlase, tšebeliso ea litšenyehelo li etsa hore e be e loketseng lits'ebetso tse fapaneng tsa indasteri. Ha indasteri e ntse e tsoela pele ho sebetsa 'me e hloka tharollo e tšepahalang le e sebetsang, ho paka ha kharane e tla lula e le khetho ea pele ho netefatsa ts'ebetso ea pele ea li-valtal tsa lisebelisoa tsa seletsa.

Bakeng sa lintlha tse ling tse hlophisehileng, ka kopo sheba khethoLibuka tsa libukaHoSebaka sa semmuso sa Hikek. Haeba u na le lipotso tsa khetho, ka kopo ikopanya le basebetsi ba lihora tse 24 tsa Hikelok.

Nako ea poso: Oct-22-2024