Welding nzira yakavimbika kwazvo nzira, iyo inoshandiswa zvakanyanya mukugadzirwa kwemaindasitiri munyika. Maitiro akakodzera ekutambisa anogona kuve nechokwadi chekuti kuunganidzwa kwakasimba kwakasimba uye kusvetuka kusununguka, saka zvinogona kuridza basa rakakosha kwazvo.

Kune maviri mafomu akajairika eWalding: Socket Welding uye Butt Welding

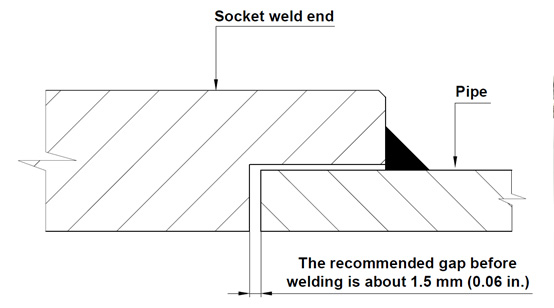

Socket Welding. Pakati pechigadziko, isa pombi muCocket Inotarisa gomba kusvikira yasvika pasi, uye wozoburitsa pombi ne1,5mm (0.06in.), Ikaita kuti tisimbise kushushikana panguva yeWelding.

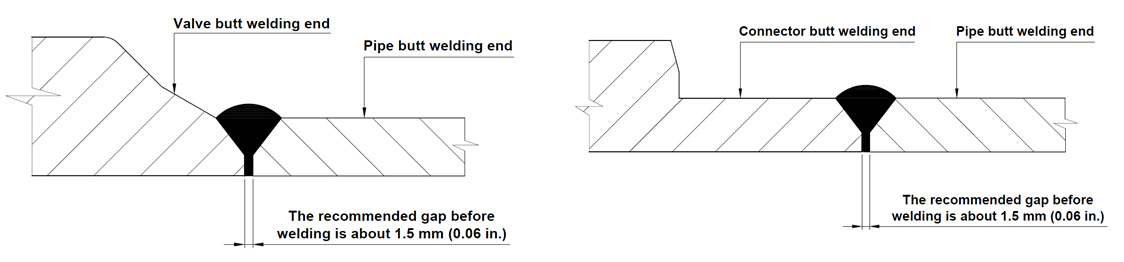

Butt Welding: Iyo Welding majoini eAldments pamativi maviri aya anozove akapesana, uye 1.5mm (0.06in.) ichachengetwa. Ipapo weld denderedzwa pamwe nemubatanidzwa kuti uve nechokwadi chekuti madziro ePipe anokwenenzverwa zvakakwana kuti awane simba rakavimbika. Sezvinoratidzwa muchimiro, vharuvhu ine butt welting connection inogona kunge yakaburitswa neyepombi, uye zvakaringana zvinhu zvinogona zvakare kunge zvakaburitswa nepombi.

Welding anotsanangura kushanda

Vashandi vaHikelok

Hikelok Welding zvigadzirwa zvinosanganisirasando vheji, Bhora vharuvhu, Weld Fitings, etc., iyo inogona zvakare kugadziriswa zvichienderana nemamiriro ekushanda evatengi.

Kuti uwane mamwe kuodha ruzivo, ndapota tarisa kusarudzwacatalogsonHikelok's official webhusaiti. Kana iwe uine chero mibvunzo yekusarudza, ndapota taura Hikelok's 24-awa online online nyanzvi yekutengesa vashandi vashandi.

Kutumira Nguva: Kubvumbi-27-2022