Taper threaded fitting is always the standard choice for various important oil and gas applications. These fittings provide acceptable performance in medium pressure applications when used with special anti-vibration nozzles and installed by knowledgeable and experienced technicians.

The disadvantage is that the installation of taper thread fitting is time-consuming and laborious. If the anti-vibration connecting pipe is not used during the installation, and it is installed by technicians who are not familiar with the installation preparation and assembly process, the leakage time of conical threaded fittings may be earlier than the operator's expectation.

What are the consequences of leakage or failure of the medium pressure fittings? Owners and operators of offshore oil and gas are under great pressure to ensure safety and environmental compliance while controlling costs and optimizing efficiency. Leakage or failure of oil and gas medium pressure fittings will cause serious problems, which will lead to unplanned maintenance and environmental and safety problems. In addition, the twin ferrule connector is the best choice for many demanding oil and gas applications, and the pre installation time of tapered threaded connectors may be longer than the corresponding installation.

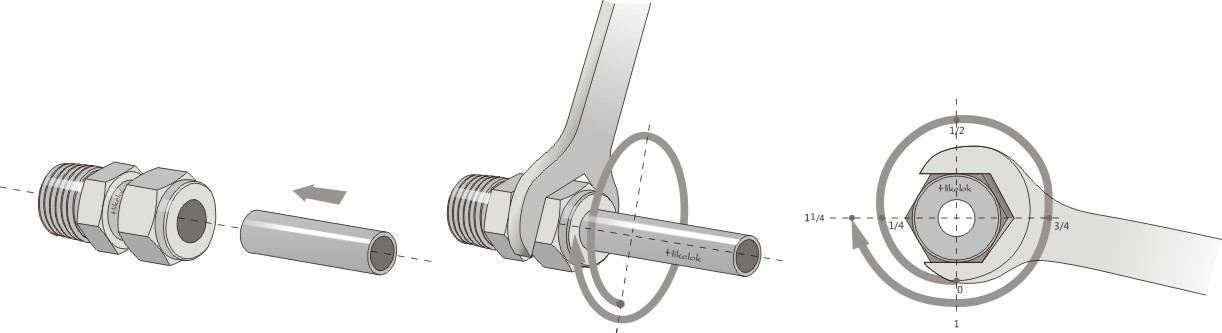

For example, many medium pressure applications can utilize ferrule connectors, which can be used in almost any application where taper threaded connectors are traditionally specified. Assembly personnel can complete Hikelok tube fittings installation, which is about five times faster than tapered and threaded fittings, thus eliminating the need for rework after facility delivery and greatly reducing the overall maintenance cost. In addition, the installation process of these ferrule connectors is simpler, and the chance of technicians making mistakes is lower, thus providing more consistent and reliable performance throughout the life cycle of the facility. These efficiency factors can save a lot of labor, thus reducing the overall cost of the upper module system (including chemical injection skid, wellhead control panel, umbilical terminal unit and hydraulic power unit).

Post time: Feb-17-2022