In the continuous supply of instrument tubes for many years, Hikelok has rich experience in what kind of tubes, fittings, control valves and other products are needed in the fluid system. After understanding the specific working conditions of customers and according to the needs of customers, Hikelok can recommend suitable tubes according to professional technical knowledge, and suggest to buy products together to facilitate installation and use, so as to make the customer's fluid system more efficient. In addition, all kinds of instrument tubes provided by Hikelok have flat nozzle without burr, no depression and scratch on the tube body, accurate size and high quality. They are suitable for bending and laying tubes, which helps customers build a safe and stable fluid system.

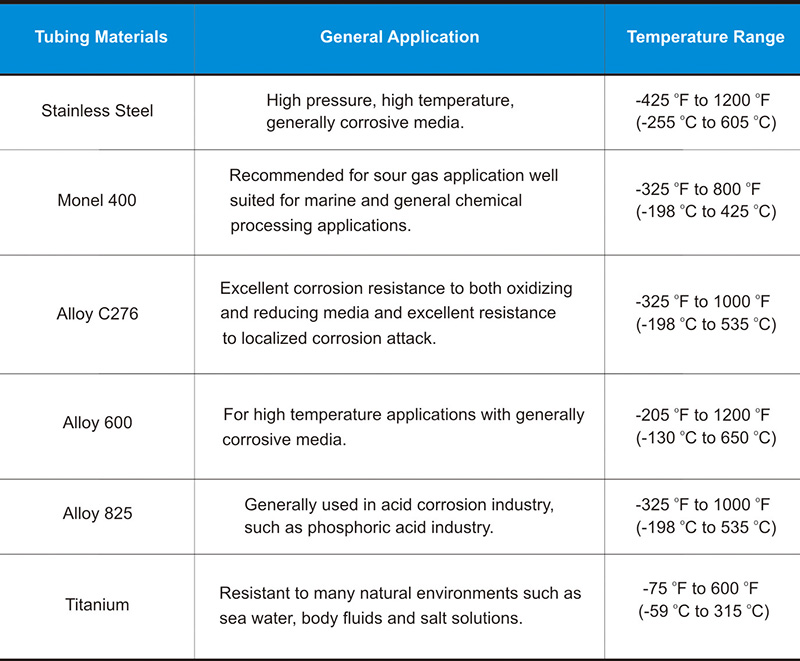

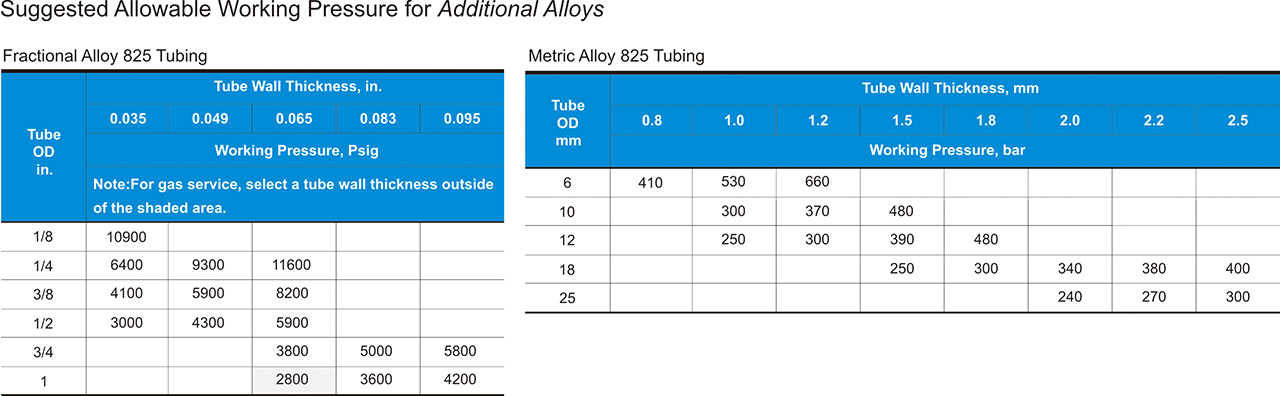

Hikelok can provide various types of instrument tubes, including seamless stainless steel tubes and alloy tubes, which comply with ASTM A269 A213 B622 and other standards. Different materials have their own temperature and pressure characteristics, which can be applied to different working conditions to meet the specific needs of customers.

When purchasing the instrument tube of Hikelok, you need to understand the following two points:

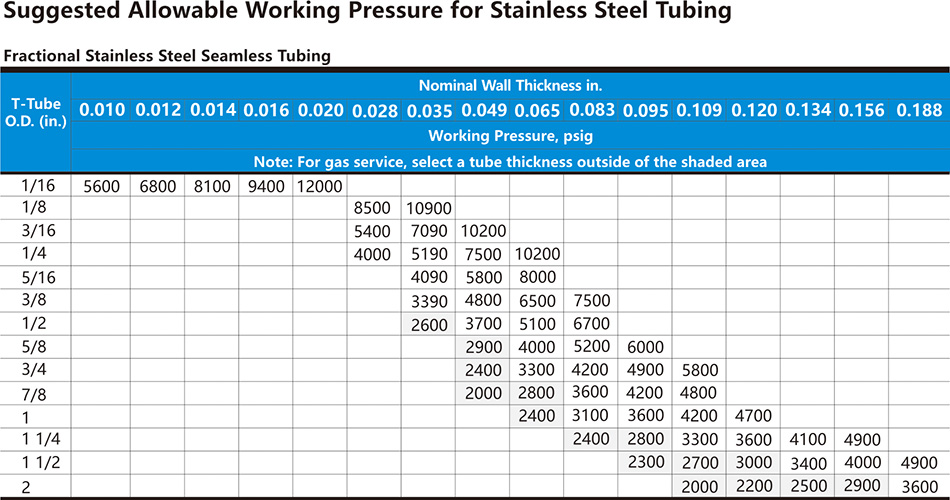

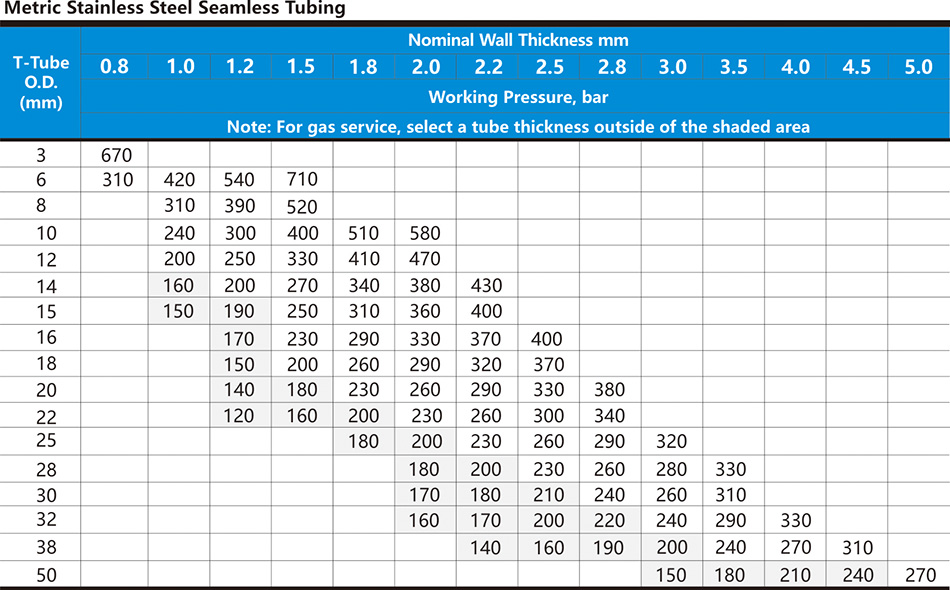

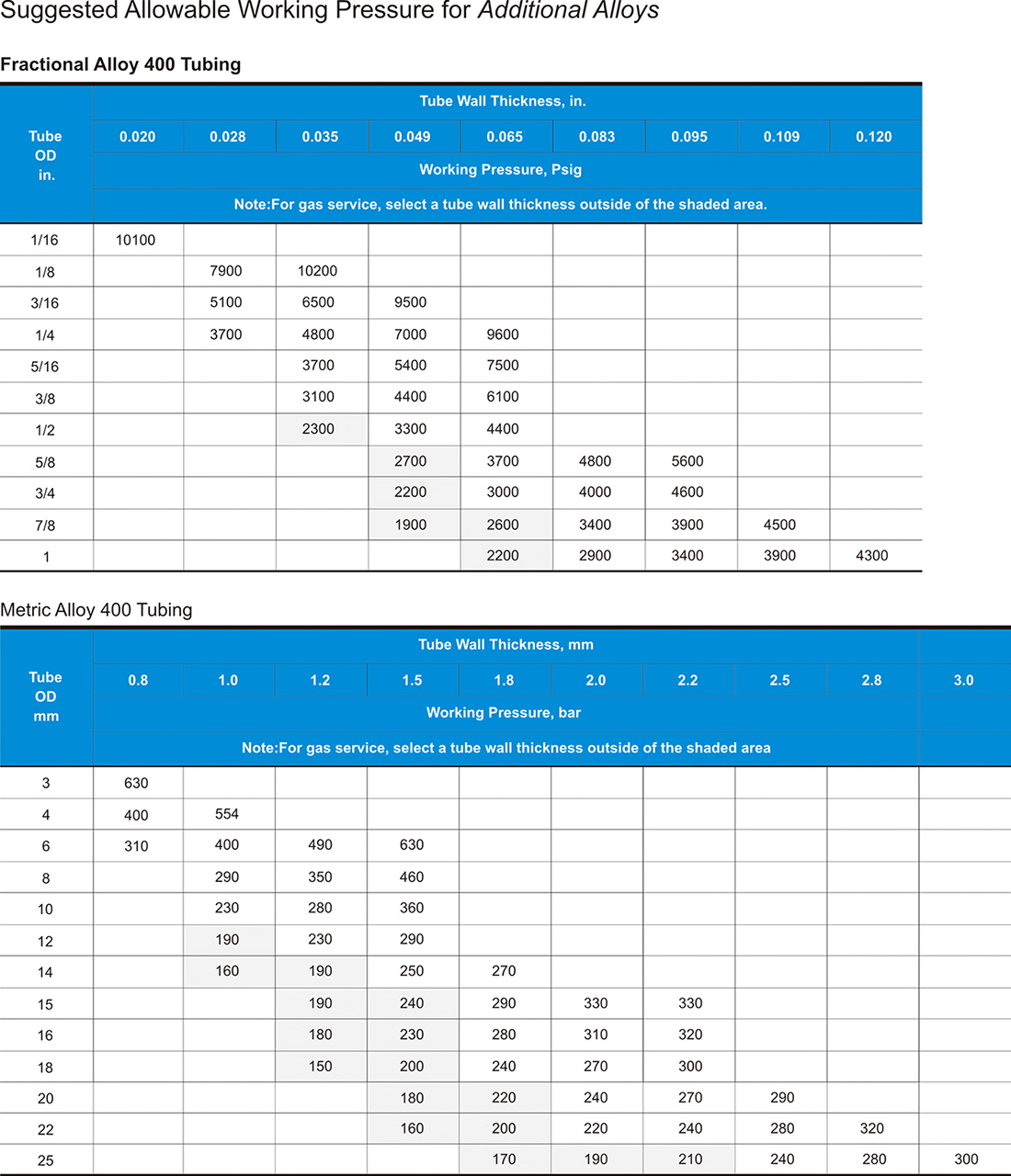

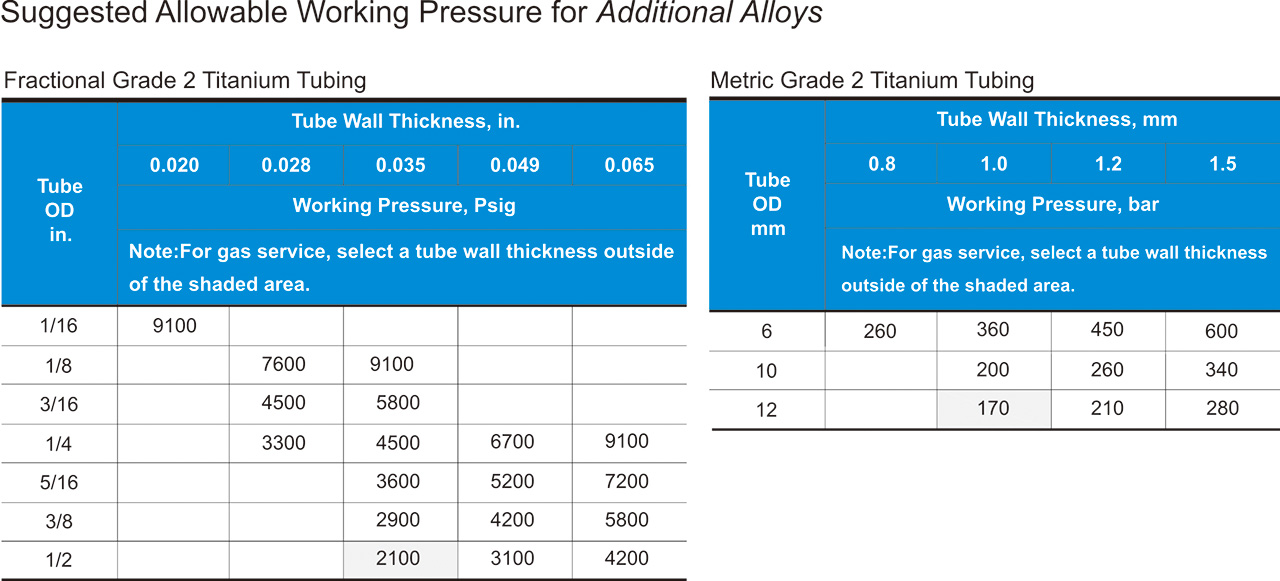

1. Working pressure of tube. When building a fluid system, it is necessary to determine the system working pressure, so as to select the material and size of the tube. In general, the high-pressure working environment requires strong tubes, such as stainless steel tubes. If it is used under high corrosion conditions, it is necessary to select tubes with high corrosion resistance, such as alloy tubes. In the pressure range of various materials shown in the table below, it should be noted that: (1) in any case, the pressure of tube fittings should not exceed the recommended working pressure; (2) In the application of gas system, the pressure value outside the shaded area should be selected to determine the parameters such as tube size and wall thickness.

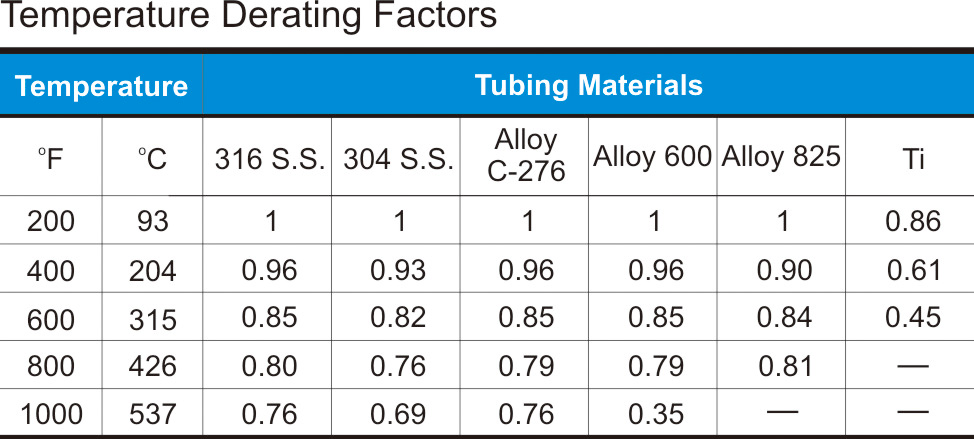

2. Working temperature of tube. Another factor should be considered when selecting the correct tube - working temperature. Stainless steel tube is suitable for high temperature environment. In low temperature environment, copper tube and aluminum tube should be selected, but alloy tube is very suitable at high working temperature. When selecting, find the correct value of temperature derating factors according to the following table, multiply it by the pressure value of the corresponding tube, and then find the tube with specific size and material according to your own demand pressure.

At the same time, in the construction of fluid system, it is recommended to cooperate with Hikelok tube cutter, tube deburring tool, tube bender and other tools for auxiliary installation.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Mar-17-2022