Threaded port products are commonly used in industrial fluid systems. Hikelok analyzed several maintenance cases and found that most of the system leakage is caused by human factors, one of which is the improper installation of threads. Once the thread is installed improperly, it will cause serious consequences. It will not only bring impurities into the fluid, resulting in fluid pollution, but also lead to the sudden situation of poor system sealing and fluid leakage, which will bring serious potential safety hazards and property losses to the factory and personnel. Therefore, correct thread installation is very important for the fluid system.

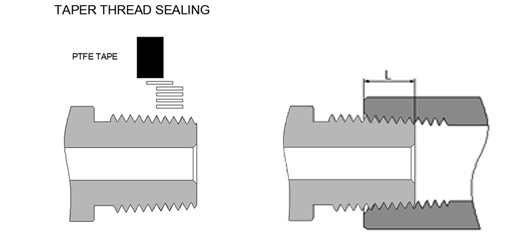

There are two types of Hikelok thread: tapered thread and parallel thread. The tapered thread is sealed by PTFE tape and thread sealant, and the parallel thread is sealed by gasket and O-ring. Compared with the two types, the installation of tapered thread is slightly more difficult, so before building the fluid system, you should master the installation steps of tapered thread and understand the installation precautions

Sealing method of PTFE tape pipe thread sealant

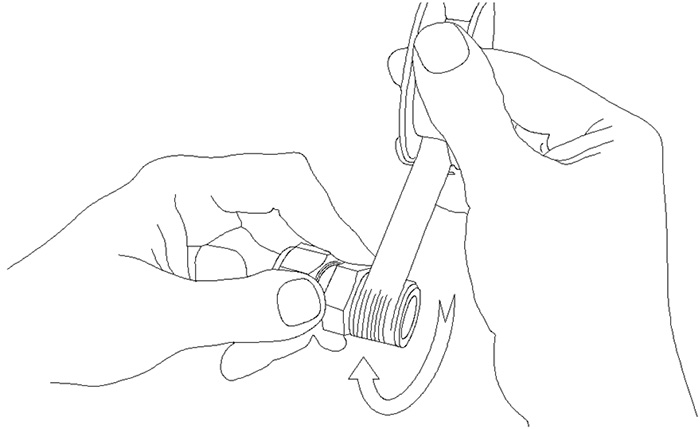

● Starting from the first thread of the male thread port, wrap the PTFE tape pipe thread sealant along the spiral direction of the thread for about 5 to 8 turns;

● When winding, tighten the PTFE tape pipe thread sealant to make it fit the thread seamlessly and fill the gap between the tooth top and tooth root;

● Avoid covering the first thread to prevent the PTFE tape pipe thread sealant from entering the pipeline and mixing with fluid after being crushed;

● After winding, remove the excess PTFE tape pipe thread sealant and press it with your fingers to make it more closely with the threaded surface;

● Connect the thread wrapped with the PTFE tape pipe thread sealant with the connector and tighten it with a wrench.

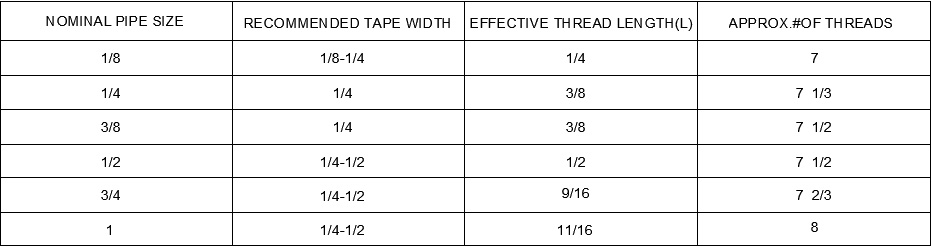

The width and winding length of PTFE tape pipe thread sealant can refer to the following table according to the thread specification.

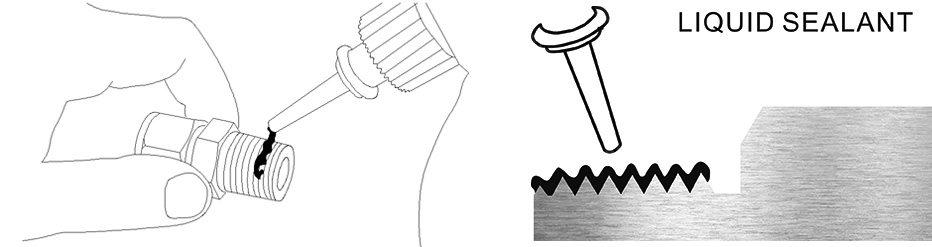

Sealing method of pipe thread sealant:

● Apply an appropriate amount of pipe thread sealant on the bottom of male thread;

● Connect the thread coated with sealant with the connector. When tightening with a wrench, the sealant will fill the thread gap and form a seal after natural curing.

Note: before installation, please be sure to check the female and male threads to ensure that the thread surface is clean, free of burrs, scratches and impurities. Only in this way can the threads be fastened and sealed after the above installation steps and ensure the safe operation of the system.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Apr-06-2022