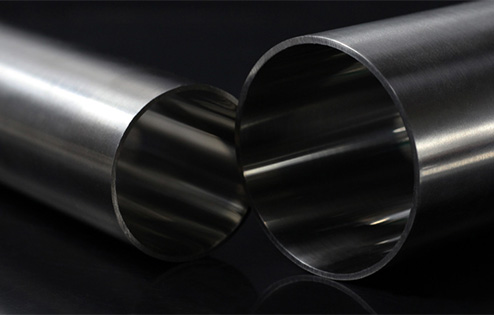

We often hear about process tubing, nominal tubing, fluid tubing, instrument tubing, metric tubing, twin ferrules tubing, seamless pipes, BA tubing, precision rolled tubing, and so on. With so many names, who is the standard name? Let's thoroughly explain the stainless steel tubing below.

To understand how stainless steel tubing are called and classified, the first and most confusing concept is to clarify: tubing and pipe. Both tubing and pipe mean pipe in English, and there is no corresponding Chinese translation. So what is the difference between them?

1. Firstly, the representation methods are different: tubing are represented by outer diameter and wall thickness, while pipe tubes are represented by NPS (nominal pipe size) nominal diameter and schedule No. wall thickness number.

2. Different standards: The standard for tubing is ASTM A269 and ASTM A213, while the standard for pipe is ASTM A312.

3. Different tolerances: The tolerance range of tubing is smaller than that of pipe. In pressure calculation, tubing can generally accurately represent pressure (psi), while pipe is usually represented by PN nominal pressure.

4. The states are different: the tubing is in an annealed state, and there is no requirement for the pipe, which is why the tube can be bent directly, while the pipe needs to be connected with an elbow.

5. Different applications: Tube has multiple specifications, so it is mostly used in instrument systems, while pipe has fewer specifications and is mostly used in power and process pipeline systems.

What is the reasonable Chinese name for "tubing" and "pipe"? We believe that it is more reasonable to correspond to "process pipe" and "instrument pipe" respectively. This distinction is based on application and is also the core difference between "tubing" and "pipe".

Other names are easier to distinguish:

1. From the perspective of forming, welded pipes are called welded pipes, while pipes formed by precision rolling and cold drawing are called seamless tubing. Seamless tubing should be classified as precision rolled seamless tubing and cold drawn seamless tubing based on their precision rolling and cold drawing forming.

2. BA tube, EP tube, acid pickling tube, and polishing tube are distinguished based on their surface condition. BA tube refers to the bright annealing of the tube, EP tube refers to the electrochemical polishing of the tube, acid pickling tube refers to the removal of the oxide layer through acid pickling passivation after the tube is processed, which is a basic state of the tube, and polishing tube refers to the mechanical polishing treatment of the outer surface of the tube.

3. As for fluid pipes and tubing, they are mainly referred to as standing at the angle of use.

4. Metric tubing are relative to fractional tubing, and they are a classification under instrument tubing. Fractional tubing are tube with diameters and wall thicknesses measured in fractional units.

5. The nominal pipe is actually a pipe, and the concept of nominal pipe can be found in the detailed explanation of Hikelok's nominal concept.

Hikelok, a professional manufacturer of instrument valves and fittings.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Jan-22-2025