Hikelok's metal hoses include MF1 hose and PH1 hose. Because their appearance is roughly the same, it is not easy to distinguish them from their appearance. Therefore, this paper analyzes their differences from the aspects of structure and function, so as to facilitate everyone to have a deeper understanding of them and make a correct choice in combination with their actual working conditions when purchasing.

Differences between MF1 hose and PH1 hose

Structure

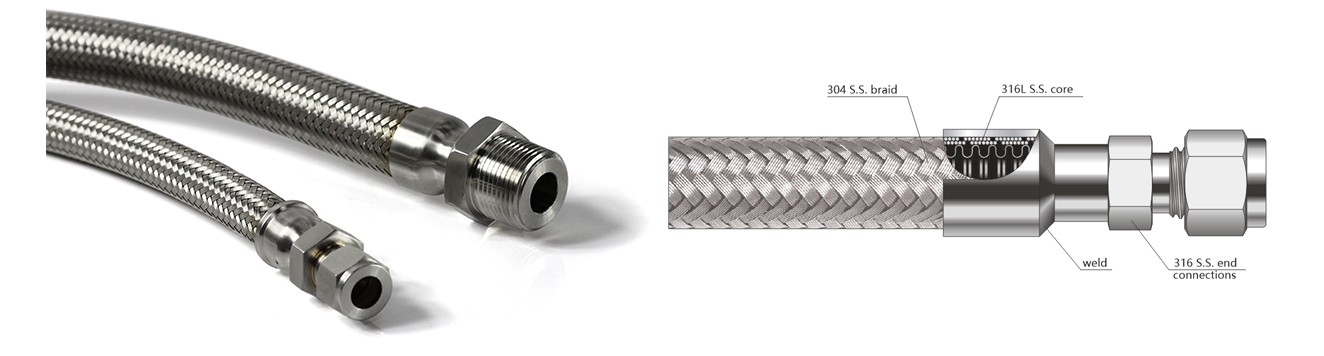

The outer layers of MF1 series and PH1 series are made of 304 braid. The braid of this structure increases the bearing pressure value of the hose, which is flexible and easy to bend. The difference lies in the material of their core tube. MF1 core tube is a 316L corrugated tube, while PH1 core tube is a smooth straight tube made of polytetrafluoroethylene (PTFE). (see the following figure for specific appearance and internal differences)

Figure 1 MF1 Hose

Figure 2 PH1 Hose

Function

MF1 metal hose has excellent performance in fire resistance, high temperature resistance and good air tightness, so it is often used in high temperature and vacuum occasions. Due to the structural design of all metal materials of the hose, the corrosion resistance of the hose is greatly improved and has no permeability. Under the working condition of corrosive transmission medium, it can also ensure safe and stable operation.

As the core tube of PH1 hose is made of PTFE, which has excellent chemical stability, chemical corrosion resistance, oxidation resistance, high lubricity, non viscosity, weather resistance and anti-aging ability, PH1 hose is often used under the working condition of conveying highly corrosive media. It should be noted here that PTFE is a permeable material, and the gas will penetrate through the voids in the material. The specific permeability will be affected by the working conditions at that time.

Through the comparison of the characteristics of the above two hoses, I believe you have a certain understanding of the two hoses, but the following factors need to be considered when selecting the type:

Working pressure

Select the hose with appropriate pressure range according to the actual working conditions. Table 1 lists the working pressure of the two hoses with different specifications (nominal diameter). When ordering, it is necessary to clarify the working pressure when using, and then select the appropriate hose according to the working pressure.

Table 1 Comparison of working pressure

|

Nominal Hose Size |

Working Pressure psi(bar) |

|

|

MF1 Hose |

PH1 Hose |

|

|

-4 |

3100(213) |

2800(193) |

|

-6 |

2000(137) |

2700(186) |

|

-8 |

1800(124) |

2200(151) |

|

-12 |

1500(103) |

1800(124) |

|

-16 |

1200(82.6) |

600(41.3) |

|

Note: the above working pressure is measured at the ambient temperature of 20 ℃ (70 ℉) |

||

Working medium

On the one hand, the chemical properties of the medium also determine the selection of the hose. Selecting the hose according to the medium used can give full play to the performance of the hose to the greatest extent and avoid leakage caused by the corrosion of the medium to the hose.

Table 2 Material comparison

|

Hose Type |

Core Tube Material |

|

MF1 |

316L |

|

PH1 |

PTFE |

MF1 series is stainless steel hose, which has certain corrosion resistance, but it is far inferior to PH1 hose in chemical corrosion resistance. Due to the excellent chemical stability of PTFE in the core tube, PH1 hose can withstand most chemical substances, and can work stably even in strong acid-base medium. Therefore, if the medium is acid and alkaline substances, PH1 hose is the best choice.

Working temperature

Because the core tube materials of MF1 hose and PH1 hose are different, their working pressure is also different. It is not difficult to see from table 3 that MF1 series hose has better temperature resistance than PH1 series hose. When the temperature is lower than - 65 ° f or more than 400 ° F, PH1 hose is not suitable for use. At this time, MF1 metal hose should be selected. Therefore, when ordering, the working temperature is also one of the parameters that must be confirmed, so as to avoid leakage of the hose during use to the greatest extent.

Table 3 Comparison of hose operating temperature

|

Hose Type |

Working Temperature℉(℃) |

|

MF1 |

-325℉ to 850℉(-200℃ to 454℃) |

|

PH1 |

-65℉ to 400℉(-54℃ to 204℃) |

Permeability

MF1 series core tube is made of metal, so there is no penetration, while PH1 series core tube is made of PTFE, which is a permeable material, and gas will penetrate through the gap in the material. Therefore, special attention should be paid to the application occasion when selecting PH1 hose.

Discharge of medium

The core tube of MF1 hose is a bellows structure, which has a certain blocking effect on the medium with high viscosity and poor fluidity. The core tube of PH1 hose is a smooth straight tube structure, and PTFE material itself has high lubricity, so it is more conducive to the flow of medium and convenient for daily maintenance and cleaning.

In addition to MF1 hose and PH1 hose, Hikelok also has PB1 hose and ultra-high pressure hose types. When purchasing hoses, Hikelok's other series of products can be used together. Twin ferrule tube fittings, pipe fittings, needle valves, ball valves, sampling systems, etc. can also be customized according to special working conditions.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: May-13-2022