Introduction: In recent years, with the rapid rise of new energy vehicles and artificial intelligence, the demand for semiconductors has continued to grow. The rapid development of intelligent technology has accelerated the transition of semiconductor size from microelectronic level to atomic level. Third generation semiconductors usher in a new era of high-quality development! At the same time, the manufacturing process is also more complex. What products from Hikelok can help with semiconductor development? Let's learn more together!

Emerging technologies such as artificial intelligence and big data are key driving forces for development, leading to the need to package greater performance into smaller chips. This means that the manufacturing process will become more complex, requiring faster response capabilities and higher component reliability to ensure high-precision chemical transportation will become a top priority.

Due to the precision and complexity of semiconductor chip manufacturing, whether it is valves for precise gas control or pipeline connectors for carrying electronic gases, they should comply with relevant ASTM and SEMI industry standards and possess the following characteristics:

1. Stainless steel raw materials must be refined using ultra-high purity VAR or VIM-VAR to ensure the requirement of ultra-high purity from the source;

2. The inner surface in contact with the medium needs to undergo processes such as electrochemical polishing and passivation to achieve ultra cleanliness while improving the corrosion resistance of the product;

3. Stainless steel and plastic products must meet relevant ASTM and SEMI industry standards such as internal humidity analysis control, total organic carbon (TOC) analysis control, and ion pollution composition control.

Hikelok's ultra-high purity series products meet the requirements of the semiconductor industry for fluid components and comply with ASTM and SEMI industry standards, including raw material selection, high standard processing technology, and assembly testing in a 100 level dust-free workshop. The product types include ultra-high purity pressure reducing valves, ultra-high purity diaphragm valves, ultra-high purity bellows sealed valves, integrated panels, ultra-high purity fittings, and EP tubing. Multiple size types are available, and customization can be made according to on-site proprietary installation requirements.

Adopting a metal to metal sealing form to achieve reliable sealing of products within the vacuum and positive pressure range. After the standard treatment process, the average roughness of the surface polishing of the ultra-high purity joint in contact with the medium can meet 10% μ In. (0.25 μ m) Ra; After ultra-high purity process treatment, the average roughness of the surface polished in contact with the medium can meet 5 μ In. (0.13 μ m) Ra. The ultra-high purity joint nut is designed with a leak detection hole, which facilitates leak detection. The nut threads are treated with silver plating process to reduce thread wear and reduce the risk of thread engagement during installation.

Miniature butt welded Fittings

The design pressure is calculated based on ASME B31.3 and ASME B31.1. The structure is compact and compact, with precise dimensions. The welding end is straight without burrs, and the wall thickness is uniform. It can achieve high compatibility with EP pipes and improve welding stability. The roughness of the inner surface of the joint can reach 5 μ In. (0.13 μ m) Ra, the average surface roughness after standard process treatment is 10 μ In. (0.25 μ m) Ra. Specially treated and cleaned joints are suitable for ultra-high purity systems, photovoltaic processes, etc., with a variety of size types to choose from.

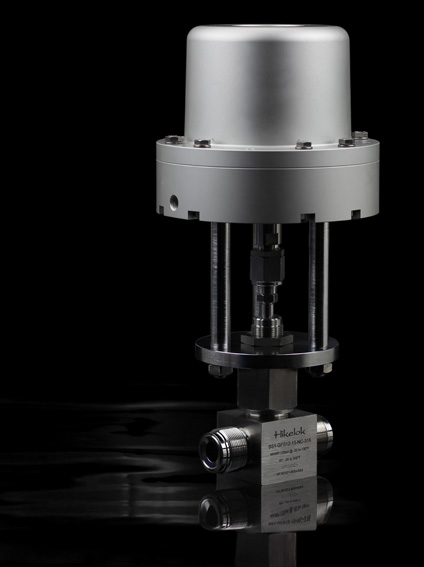

The working pressure can reach 1000 psig (68.9 bar) and the maximum temperature resistance is 482 ℃ (900 ℉). We can provide 316L, 316L VAR stainless steel and various alloy materials. The valve stem connection design can ensure reliable movement of the valve stem. The non rotating valve head design reduces wear in the valve seat area, and the precision formed corrugated pipe provides reliable sealing performance and service life. The stroke of the corrugated pipe is strictly controlled, effectively improving the safety and service life of the corrugated pipe.

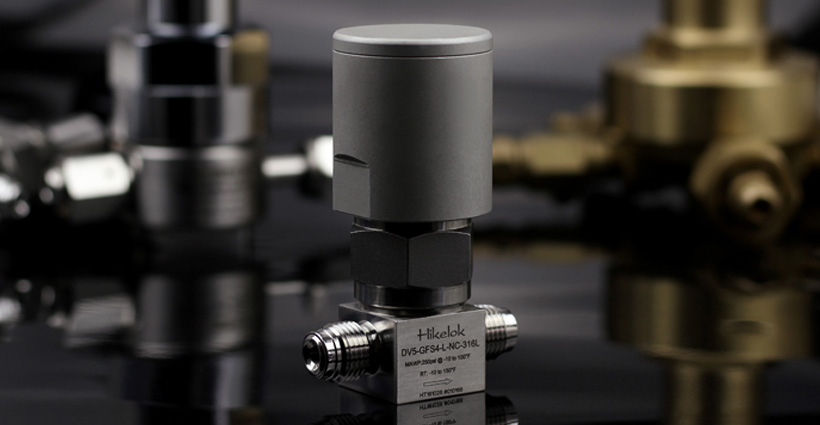

The working pressure can reach 500 psig (34.4 bar) and the maximum temperature resistance is 93 ℃ (200 ℉). 316L and 316L VAR stainless steel materials, default PCTFE valve heads are compatible with most media, and PI (polyimide) valve heads can be provided. The safe and reliable joint valve cap design, precision formed corrugated pipe provides reliable sealing performance and service life, making the sealing of the corrugated pipe valve safe and reliable. The specially designed drive valve stem is smooth.

The working pressure can reach 375 psig (25.8 bar) and the maximum temperature resistance is 82 ℃ (180 ℉). 316L stainless steel material with high flow design. The valve stem connection design ensures reliable movement of the valve stem, and the non rotating valve head design reduces wear in the valve seat area. The Y-shaped valve body design ensures that the inlet and outlet of the valve are located on the same axis, providing high flow rate and reducing flow resistance. Electrochemical polishing treatment on the inner surface, clean and smooth. Featuring high flow rate, high sealing performance, and high safety, it is the best choice for high-purity process gas distribution systems, purification systems, filtration systems, and high-purity chemical distribution systems.

This is a pressure regulating device, mainly used to control the pressure of upstream and downstream and the system, automatically adjust online, and monitor the feedback system pressure value in real time. The maximum import pressure of the product can reach 3500psig (241bar), and the outlet pressure range is selected according to the actual labor situation. Multiple valve seat sealing materials are selected, which can be used in corrosive gases and special gas situations, suitable for various working conditions and environments. The internal surface of the product is electrochemically polished to 10 inches (0.25) μ m) Ra, the diaphragm and valve body are fully metal sealed with high reliability.

High pressure (3045psig/210bar) and low pressure (250psig/17.2bar) dual types are available for selection. 316L VAR and 316L VIM-VAR valve body materials are available, with multiple options for manual and pneumatic operation. The fully enclosed PCTFE valve seat design uses Elgiloy diaphragm material to improve strength and corrosion resistance, with a long service life and an internal surface electrochemical polishing of up to 5uin (0.13) μ m) Ra, the helium detection leakage rate is less than 1 × 10-9 std cm3/s

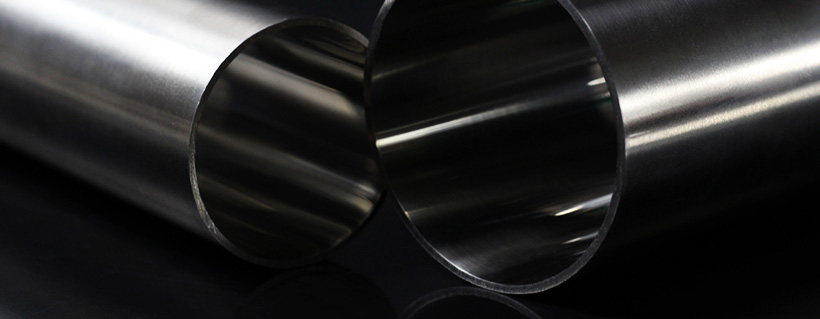

EP tubing

Internal surface electrochemical polishing with a roughness of 10 μ In. (0.25 μ m) Ra, the outer surface has undergone mechanical polishing, acid washing and other processes, presenting a bright overall state. 4 times the safety factor to ensure safe and reliable use.

The above are the preferred applications in the semiconductor industry. Hikelok keeps up with the development trend of the semiconductor industry and utilizes its rich product application experience to bring more high-performance and high-quality products to the industry! For more ordering details, please refer to the Hikelok official website selection manual. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: May-09-2024