When designing a sealed instrument system, the first step to ensure the safety and reliability of the system is to select the appropriate instrument tube to achieve the expected purpose. Proper instrument pipe plays an important role in connection and is compatible with other components. Without proper instrument pipe, system integrity is incomplete. Hikelok instrument pipe fittings are widely used in various occasions requiring the best performance of products. The compatibility of Hikelok instrument fittings and selected instrument tubes is essential to provide consistent high reliability.

1. Material compatibility

The most important factor to consider when selecting suitable instrument pipes for different applications is the compatibility between the pipe and the medium contained.

2. Hardness of instrument tube

The key is to choose the pipe material with less hardness than the pipe material. For example, stainless steel pipe hardness should be RB 80 or lower. Hikelok tubing has been tested on RB 90 hardness grade pipe, and the test performance is excellent.

3. Wall thickness

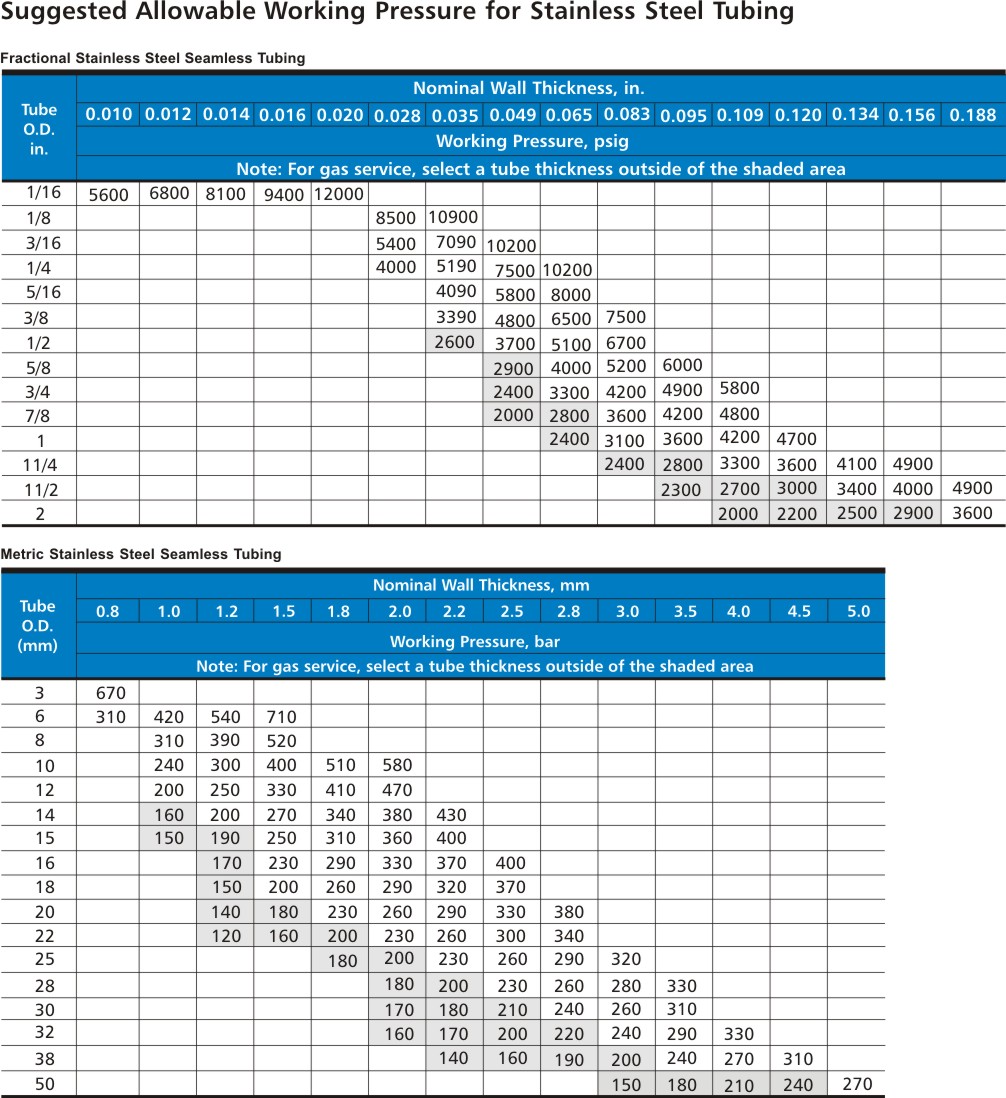

Appropriate wall thickness is necessary to meet the recognized factor of safety associated with the working pressure. The instrument tube diagram in Hikelok public information lists the combination of OD size and wall thickness of tubing. It is forbidden to use the instrument tube whose wall thickness exceeds the value specified in the chart.

All working pressures are calculated in accordance with ASME B31.3 Specification for Chemical Plant and Refinery Instrumentation and ASME B31.1 Power Instrumentation. All calculations have been validated by rigorous and extensive testing procedures at Hikelok R & D laboratories. Each calculation uses an allowable stress value, which includes a safety factor of 4:1.

All the tests are designed to simulate the actual working environment as much as possible. Hikelok does not support the failure of the instrument tube at some point, because it does not really represent the role of Hikelok products in "real-time" applications.

4. High temperature

The pressure of the tubing assembly should not exceed the recommended working pressure. Dual certification grades, such as 316 / 316L, meet the minimum chemical and mechanical properties requirements of the two alloy grades.

Post time: Feb-22-2022