In order to verify the performance of twin ferrule tube fittings in terms of corrosion resistance, sealing, pressure resistance and vibration resistance, we sampled products from different batches in strict accordance with ASTM F1387, ABS and nuclear grade joint specifications, and carried out the following experimental tests. The results show that they all pass.

Experimental test

|

Product |

Test type |

Testing process |

Test result |

|

Double ferrule tube fittings |

Vibration test |

The vibration test is carried out in the X, Y and Z directions of the test piece respectively. The test frequency is between 4 ~ 33hz, and there is no leakage during the test process. |

Pass |

|

Hydraulic proof pressure test |

The test medium is clean water, the test pressure is 1.5 times the working pressure, the pressure holding time is 5min, and the fitting is free of deformation and leakage. |

Pass |

|

|

Corrosion resistance test |

The salt spray test of stainless steel fitting was carried out for 168 hours, and there was no rust spot. |

Pass |

|

|

Pneumatic proof test |

The test medium is nitrogen, the test pressure is 1.25 times the working pressure, and the pressure is maintained for 5min without leakage. |

Pass |

|

|

Impulse test |

The pulse pressure rises from 0 to 133% of the working pressure, and then reduces the pressure to no more than 20 ± 5% of the rated pressure. The sum of a pressurization period and a decompression period is a cycle. After the cycle is not less than 1000000 times, there is no leakage. |

Pass |

|

|

Dismantling and reassembly test |

No less than 10 times of interpenetration and reassembly in each experiment without leakage. |

Pass |

|

|

Thermal cycle test |

Under the working pressure, the test piece shall be kept at low temperature - 25 ℃ for 2 hours, and the test piece shall be kept at high temperature 80 ℃ for 2 hours. From low temperature to high temperature is a cycle, which lasts for 3 cycles. After hydraulic test, there is no leakage. |

Pass |

|

|

Pull off test |

Apply a constant tensile load at a speed of about 1.3mm/min (0.05in/min). At this speed, reach the calculated minimum allowable tensile load value, the ferrule is not separated from the fitting, and there is no leakage and damage in the hydrostatic test. |

Pass |

|

|

Bending fatigue test |

1. The specimen reaches the bending strain value required by F1387 under the rated working pressure, 2. The position from zero change point to the maximum positive strain position, from zero change point to the maximum negative strain position, and from the maximum negative strain to the neutral point is a cycle. 3. Conduct 30000 total cycles on the test piece, and there is no leakage during the test. |

Pass |

|

|

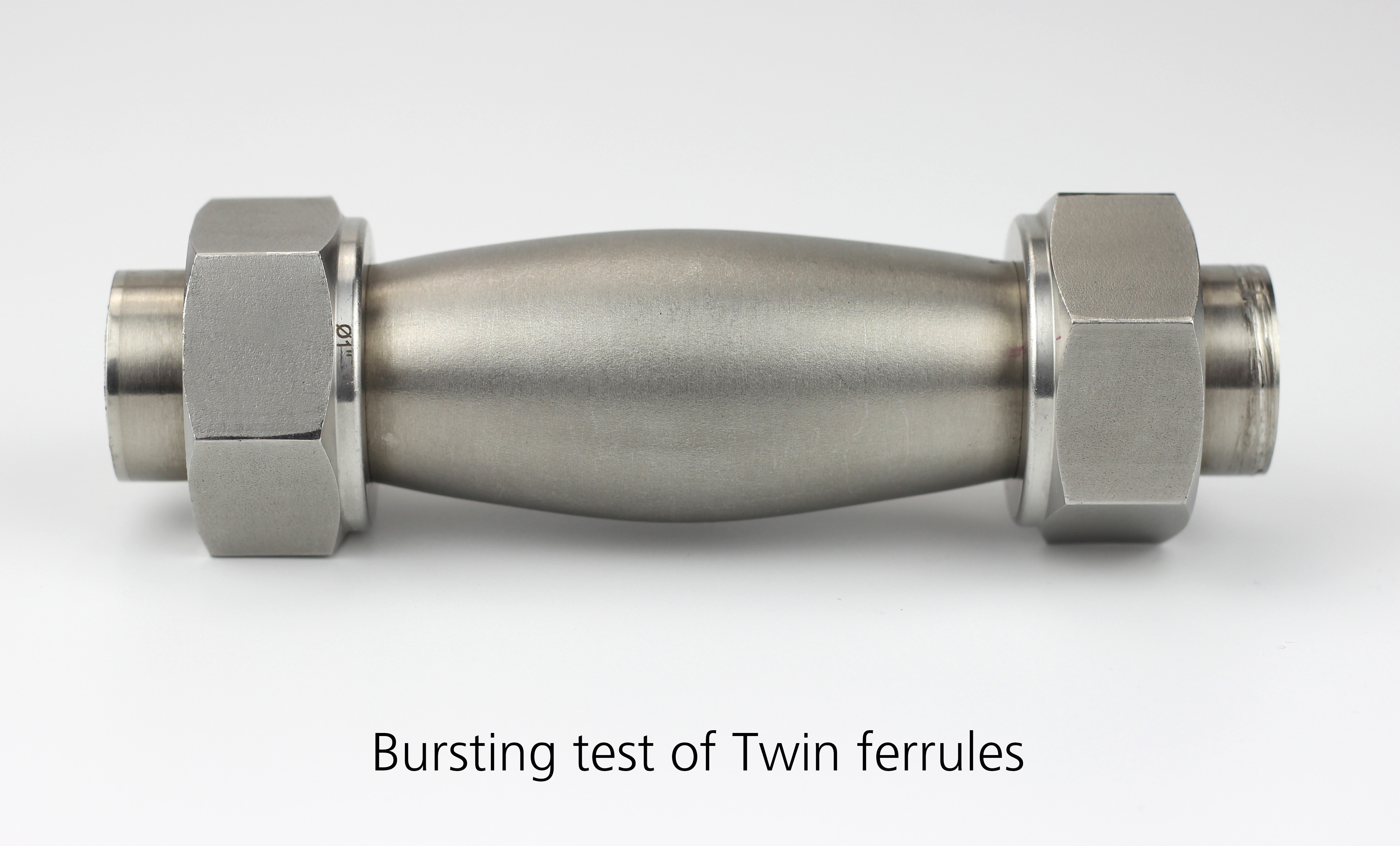

Bursting pressure test |

Pressurize the test piece more than 4 times the working pressure until the tube bursts, and the ferrules are free from falling off and leakage. |

Pass |

|

|

Rotational deflection test |

1. Introduce a bending moment according to F1387 and lock it in place. 2. Pressurize the test piece to a minimum static pressure of 3.45mpa (500PSI).Maintain bending moment and pressure during the test. 3. Rotate the test piece for at least 1000000 cycles at a speed of at least 1750 rpm, and there is no leakage in the hydrostatic test. |

Pass |

|

|

Over torque test |

Clamp the test piece with a suitable tool and rotate the other end until the tube is permanently deformed or displaced relative to the fitting and there is no leakage in the hydrostatic test. |

Pass

|

For more ordering details, please refer Hikelok official website. If you have any selection questions, please contact 24-hour online professional sales personnel.

Post time: Feb-24-2022