The dielectric fittings of Hikelok is mainly used for gas transportation, oil exploitation and other pipelines. It can allow the medium fluid to flow fully, and interrupt the artificially made anti-corrosion current or the external natural current, so as to isolate the monitoring instrument from the current. It has both electrical insulation and fluid sealing. Its internal insulation sleeve can provide high dielectric strength, excellent chemical resistance and low water absorption. It is an important condition for realizing the insulation function of the dielectric fittings.

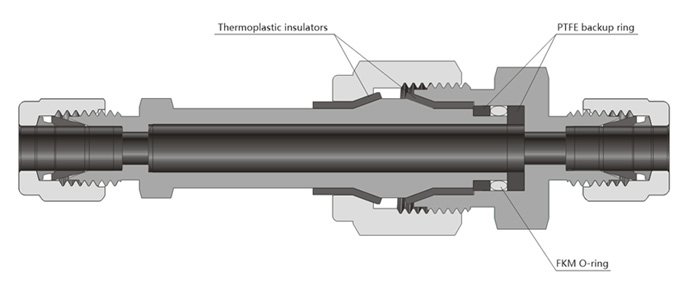

Structure

The core components of the dielectric fittings are FKM O-ring, PTFE backup ring and polyamide-imide insulator. The O-ring and PTFE backup ring can play a good sealing and insulation effect, and the thermoplastic insulator can separate the contact between the nut and the body, so that the dielectric fittings can obtain excellent insulation performance.

Material

The dielectric fittings body is made of 316 stainless steel, which has excellent corrosion resistance and can work in various harsh environments for a long time.

Connection

The connection end of dielectric fittings has multiple connection forms, such as double ferrule, NPT, BSPT, ISO/MS, etc.

Operating characteristics

Insulation resistance: when the temperature is 70 ℉ (20 ℃), and the DC voltage is 10V, the resistance is 10×Ω。

Rated working pressure: 5000 psig (344 bar).

Operating temperature range: -40℉ to 200℉ (-40℃ to 93℃).

Hikelok dielectric fittings are often used together with tubing, double ferrule tube fittings, threaded pipe fittings and other products to ensure the safe and smooth operation of the system.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Jul-06-2022