Introduction: Compared to other ball valves, Hikelok's BV3 series ball valves have a compact structure and are suitable for lower pressure conditions. At the same time, they are more affordable and suitable for water, oil, natural gas, and most chemical solvents. They can be widely used on land and sea. For more details about BV3 series ball valves, welcome to learn!

1. Introduction to BV3 Series Ball Valves·

The main characteristics of BV3 series ball valves are the use of:

a. Compact and economical design, using hexagonal bars as valve bodies

b. Free floating ball design for valve seat wear compensation

c. Anti release valve stem and standard lever handle

2. The main structure and materials of BV3 series ball valves

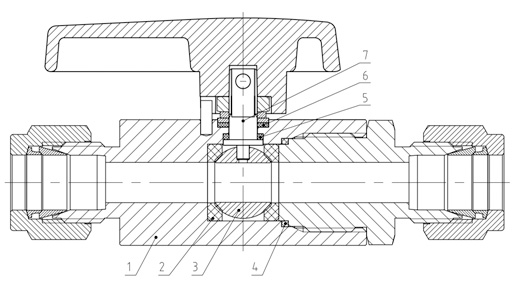

The main structure of BV3 series ball valves is shown in the figure. The handle is made of die cast aluminum alloy. The body (1), ball (3), and stem (7) are all made of 316 stainless steel. The seat (2), sealing ring (4), stem bearing (5), and stem packing (6) are made of PTFE material, which is resistant to corrosion from most media and has a reliable seal.

3. Characteristics

a. BV3 series ball valves have multiple diameters available: 7.1mm, 9mm, 12.7mm, 15mm, 19mm

b. Working temperature range: -30~400 ℉ (-34~204 ℃)

c. Rated working pressure: 1500psig (10.3Mpa)

d. Hexagonal bar valve body, compact and economical overall.

e. Interface connection forms: Multiple connection forms such as double card sleeve, NPT, BSPT, etc.

4. Application scenarios of BV3 series ball valves

The BV3 series ball valves are suitable for water, oil, natural gas, and most chemical solvents, and can provide safe and reliable performance for a wide range of onshore and offshore applications, such as water, oil, natural gas, petrochemicals, and general applications.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: May-23-2024