Introduction: In Hikelok's continuous supply of ball valves for many years, there is a type of ball valve that can be used for environmental and heating process applications, as well as for water, oil, natural gas, and most chemical solvents - that is our BV2 series ball valve. In addition, it can also be used in the hydrogen energy industry, and has a wide range of applications in other industries such as automobiles, chemicals, electricity, new energy, petroleum, etc. Let's get to know it systematically today.

1、 Introduction to BV2 Series Ball Valves

The main feature of BV2 series ball valves is the use of an integrated valve body, integrated valve seat, and integrated valve stem, which means that the valve stem and ball are integrated. The valve seat is designed as an unconventional two piece type, and the wrapped valve seat is used, with good sealing performance.

2、 The main structure and materials of BV2 series ball valves

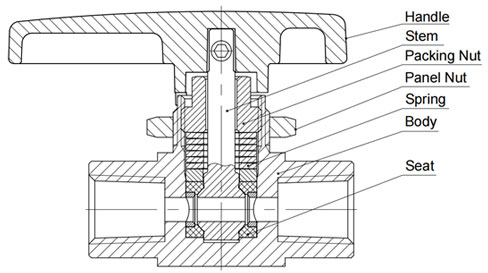

The main structure of BV2 series ball valves is shown in the figure. The handle is made of die cast aluminum alloy, and the valve stem, packing nut, and valve body are all made of 316 stainless steel. The panel nut is made of 630 stainless steel, which has high hardness. The valve can be fixed on the panel through this nut. The packing nut rotates downward to press the valve seat tightly, making the valve seat and valve ball tightly fit. The spring acts as pressure compensation in it, and can still make the valve seat and valve ball tightly fit when the valve seat is worn. The valve seat is made of PTFE material, which is resistant to most media corrosion and has a very reliable seal.

3、 Characteristics

(1). BV2 series ball valves have multiple diameters available: 1.32mm, 1.57mm, 2.4mm, 3.2mm, 4.8mm, 7.1mm, 10.3mm

(2). Maximum operating temperature range: -65~300 ℉ (-53~148 ℃)

(3). Rated working pressure: 3000psig (20.6Mpa)

The above temperature range and rated working pressure may vary depending on factors such as diameter, and are not suitable for all sizes of valves mentioned above. For specific temperature and pressure parameters, please consult online professional sales personnel.

4、 Advantages

(1). The top spring can improve thermal cycling performance and make online adjustments to the valve.

(2). The integrated valve seat reduces potential leakage points and does not require system pressure to seal.

(3). It can be installed with small pneumatic actuators or electric actuators to achieve pneumatic or electric control.

(4). It has functions of switching and cross switching.

(5). There are various types of connections, including twin ferrule, NPT, BSPT, and other types of connections.

The BV2 series ball valves are usually connected and used together with products such as tubing, twin ferrule tube fittings, pressure reducing valves, proportional relief valves, etc., to achieve complete pipeline system control functions and ensure safe and smooth operation of the system.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Mar-26-2024