In industrial applications, the selection of instrument valve packing materials is critical to ensuring optimal performance and service life. Among the various options available, graphite fillers stand out for their unique properties and numerous benefits. This article explores the benefits of graphite packing specifically for instrumentation valves, highlighting why it is the first choice for many industries.

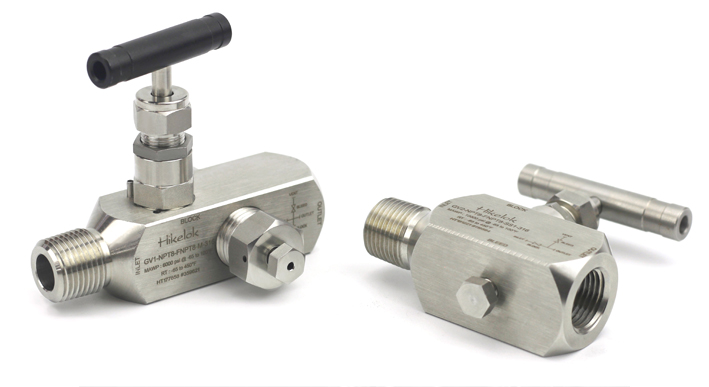

Hikelok can provide various of instrument valves that with graphite packing, such as Ball Valves, Manifolds, Needle Valves, Gauge Valve, Block and Bleed Valve etc.

Excellent temperature resistance

One of the most significant advantages of graphite filler is its excellent temperature resistance. Graphite can withstand extreme temperatures, in some cases, from cryogenic temperatures to over 500°C (932°F). This makes it ideal for instrumentation valves operating in high-temperature environments such as oil and gas, chemical processing and power generation. The ability to maintain integrity under such conditions ensures that the valve operates effectively without the risk of leakage or failure.

Excellent chemical compatibility

Instrument valves typically handle a variety of fluids, including corrosive chemicals and aggressive media. Graphite fillers offer significant chemical resistance, making them suitable for use in environments where traditional fillers may degrade or fail. Its inert nature allows it to withstand exposure to acids, bases and solvents, ensuring the packaging remains intact and functional over time. This chemical compatibility not only extends the life of the packing, but also reduces maintenance costs associated with frequent replacement.

Low friction and wear

Another advantage of graphite fillers is their low friction properties. When used in instrument valves, graphite packing minimizes wear on valve stems and other components, resulting in smoother operation and reduced energy consumption. This feature is particularly beneficial in applications where the valve cycles frequently or is subject to high pressures. The reduction in friction also helps reduce heat generation, further improving the overall efficiency of the system.

Self-lubricating properties

Graphite is a natural lubricant, which means it provides self-lubricating properties when used as a filler. This feature is particularly beneficial in instrument valves because it helps reduce the need for additional lubricant, which can sometimes interfere with the operation of the valve or contaminate the media being processed. The self-lubricating properties of graphite packing ensure smooth operation of the valve even under harsh conditions.

Versatility and customization

Graphite fillers are versatile and can be customized to meet specific application requirements. It can be manufactured in a variety of forms, including braided, molded or extruded shapes, providing tailor-made solutions for different types of instrument valves. This adaptability makes graphite fillers suitable for use in a variety of industries, from pharmaceuticals to petrochemicals, ensuring they can meet the unique needs of each application.

Cost Effectiveness

While the initial cost of graphite fillers may be higher than some traditional fillers, the long-term benefits often outweigh the upfront investment. Graphite filler’s durability, low maintenance requirements and long service life contribute to significant cost savings over time. By reducing replacement frequency and minimizing downtime, companies can achieve a more cost-effective solution for their instrumentation valves.

Conclusion

In summary, the advantages of graphite packing for instrument valves are numerous and compelling. Its superior temperature resistance, excellent chemical compatibility, low friction, self-lubricating properties, versatility and cost-effectiveness make it ideal for a wide range of industrial applications. As the industry continues to evolve and require more reliable and efficient solutions, graphite packing will undoubtedly remain the first choice to ensure optimal performance of instrument valves.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Oct-22-2024